Caution: Do not mix up these strategies

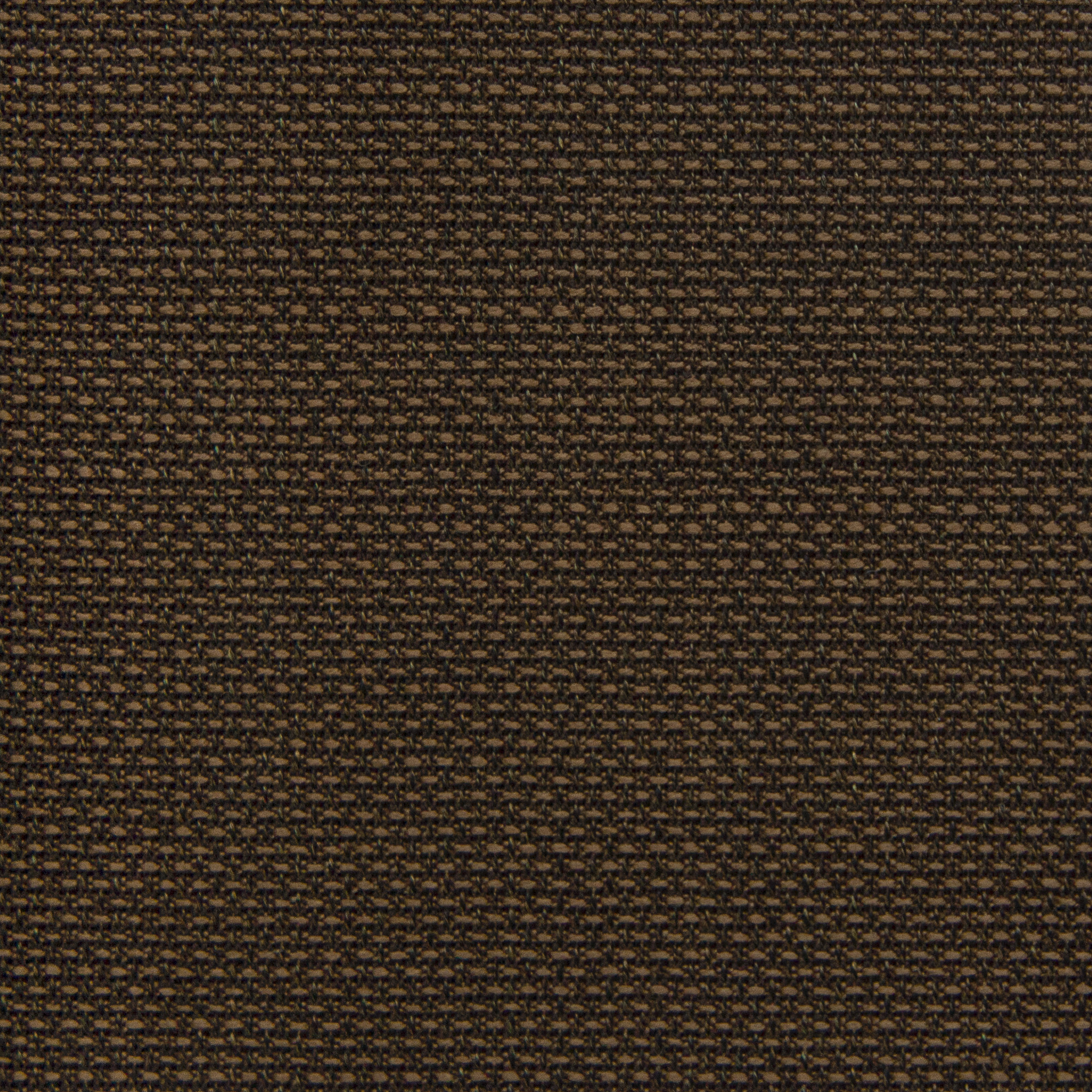

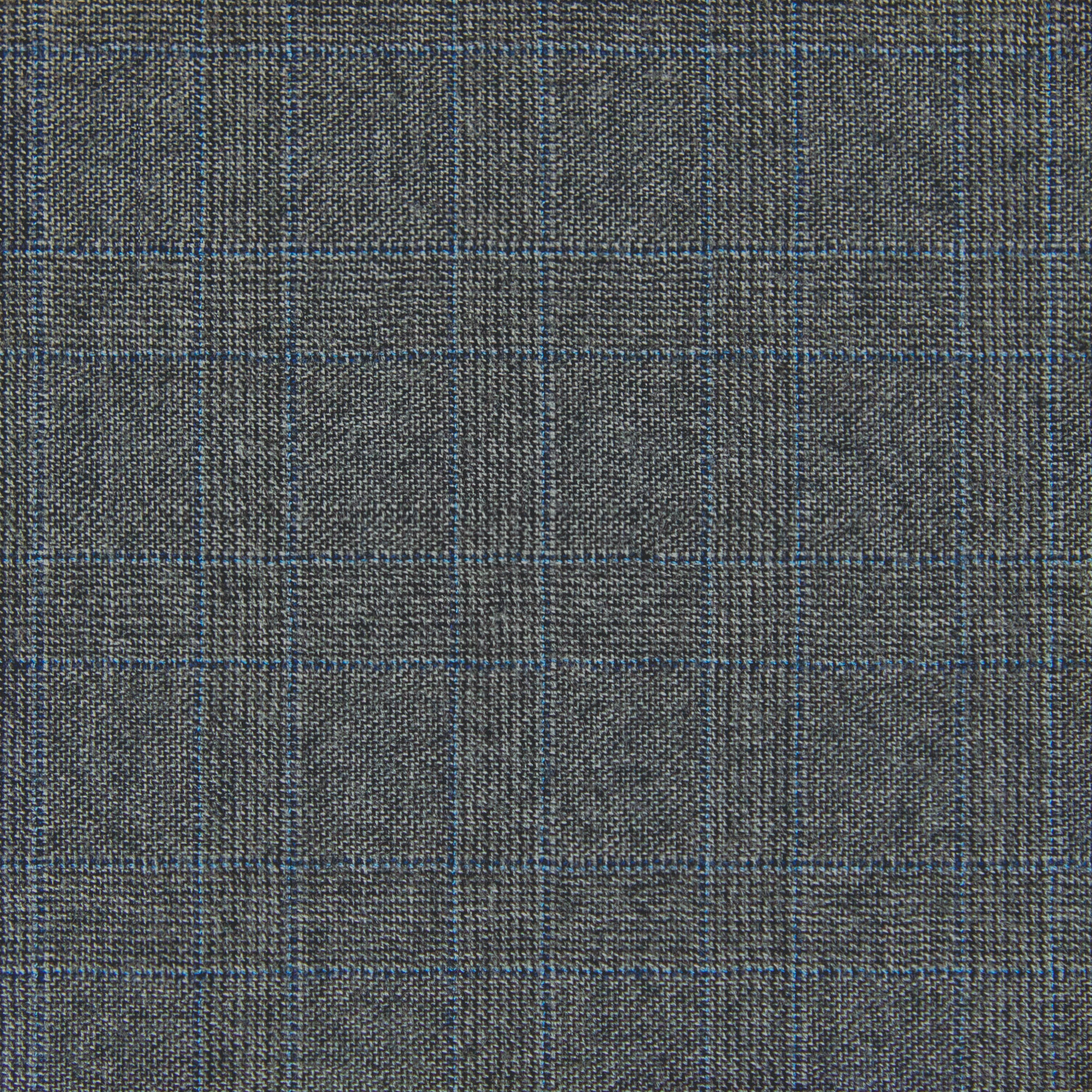

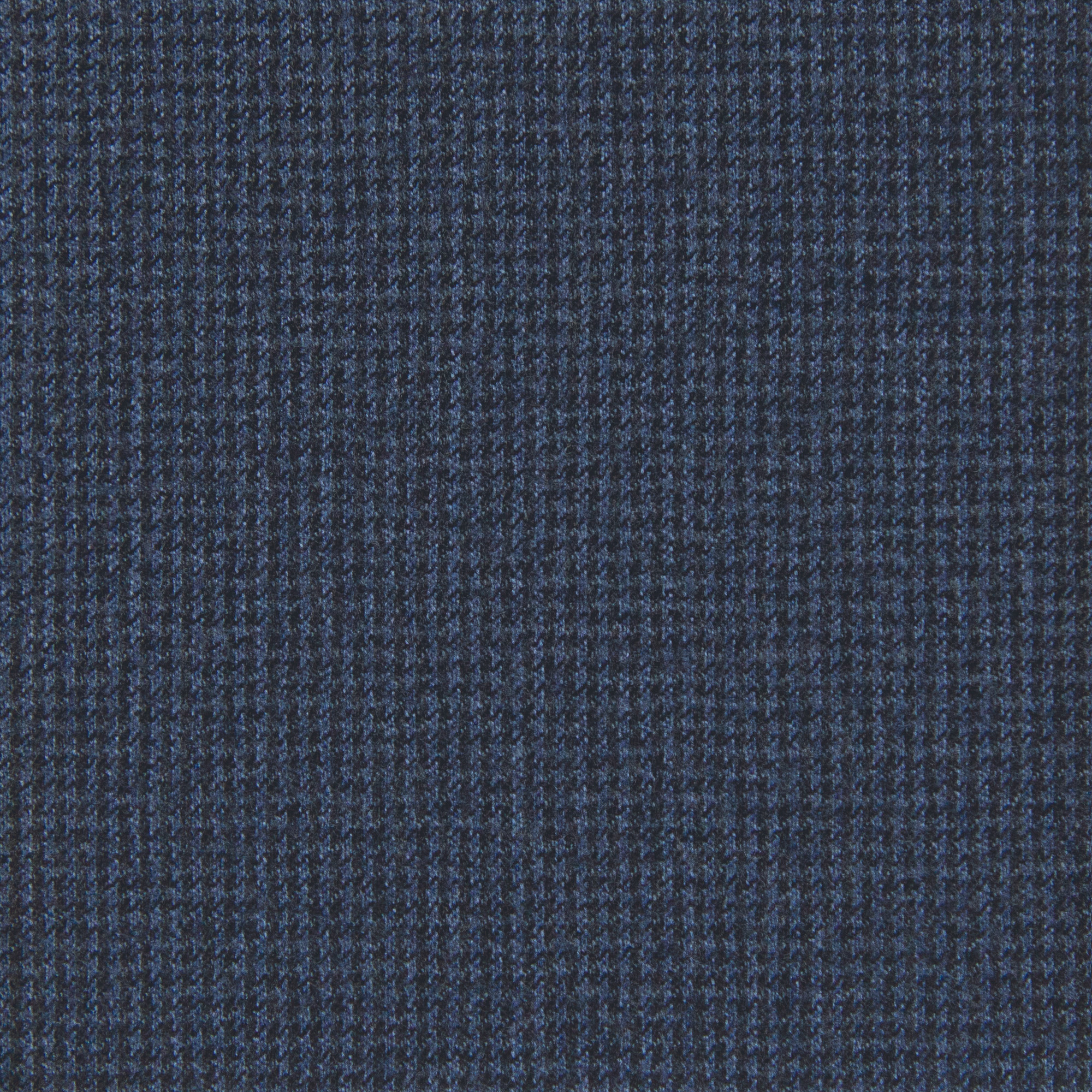

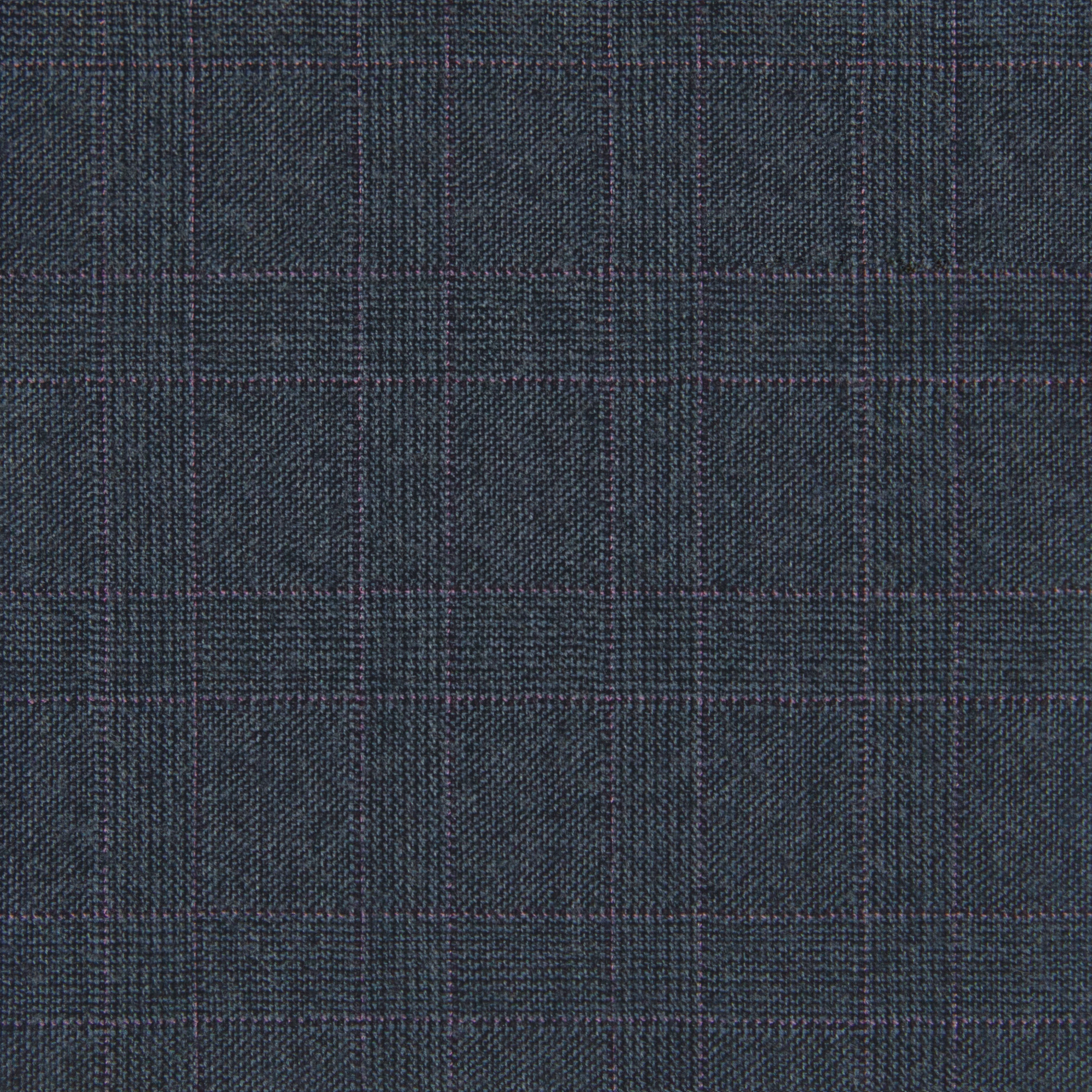

Imagine if Boyd tried to apply Motwani’s approach, or vice versa. TrackingFirst’s customers wouldn’t pay a custom-built software price, and Senszio’s customers don’t want the fit and style (or lack thereof) that come with off-the-rack clothes.

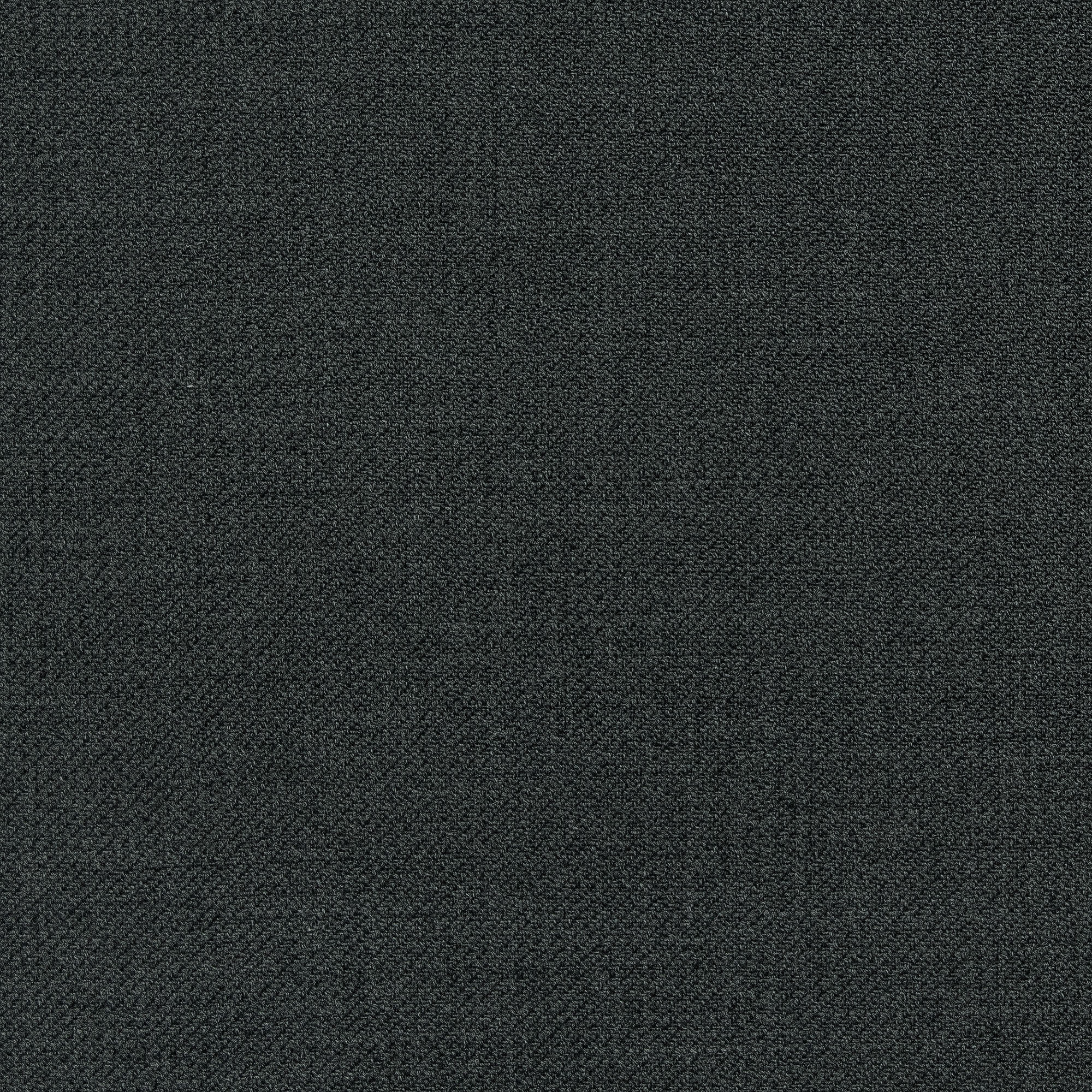

Savvy entrepreneurs are constantly seeking to increase alignment between their business strategy and their target customers’ desired outcomes. Understanding the impact of the production facility versus job shop continuum is a critical part of this strategic alignment.

Which approach is best?

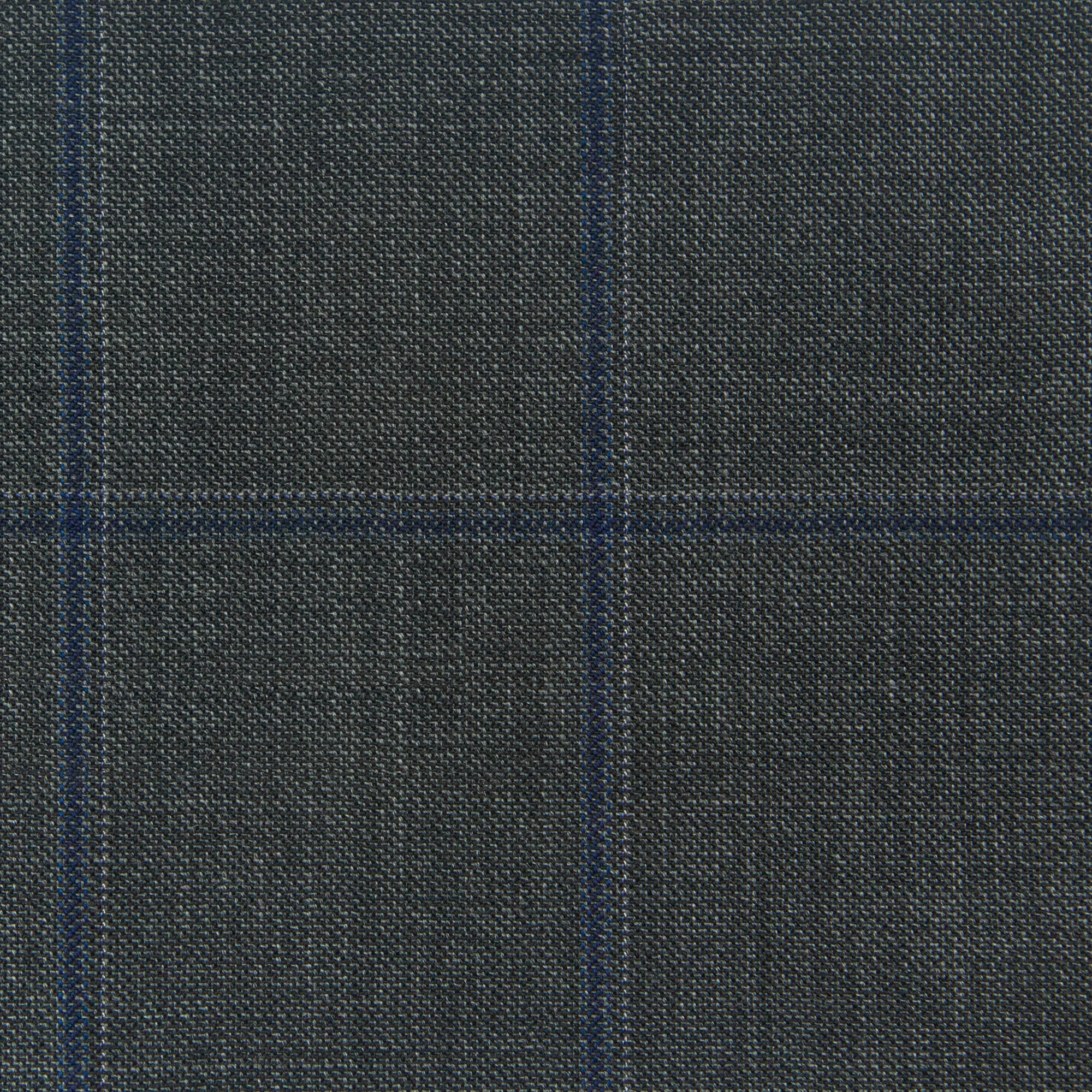

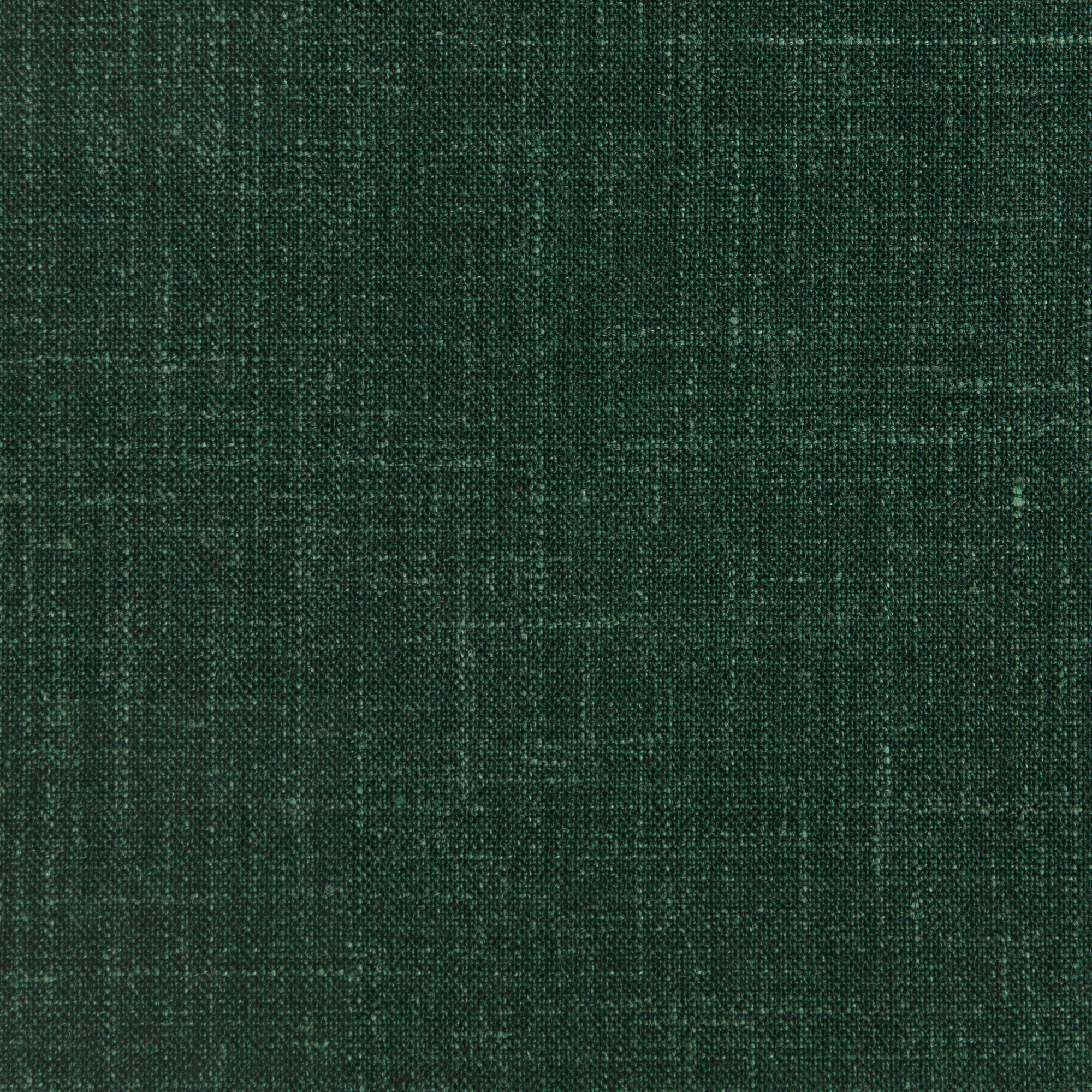

Many entrepreneurs think the production-facility strategy is the only way to go. Just ask John Boyd. But a mass migration by businesses toward scalability, at the expense of the singular customer experience, can open up a competitive advantage in any industry for the job-shop entrepreneur. Just ask Mark Motwani’s well-dressed customers.