From Sheep to Suit – How your bespoke Suit is made (Part 2)

At Senszio, we have more than 3000 fabrics from which customers can choose for their bespoke suits. We covered the raw material process procurement from the sheep throughout the industry in our previous post.

Now, here’s the stringent process we go through when crafting one-of-a-kind suits, jackets, overcoats and tuxedos.

Appointments

Four times a year, our team flies to around 15 cities all over the world. Before setting off, we’ll have made an appointment with you and we’ll meet you in our comfortable hotel suite. There, we measure you and you choose your preferred style of suit and fabric.

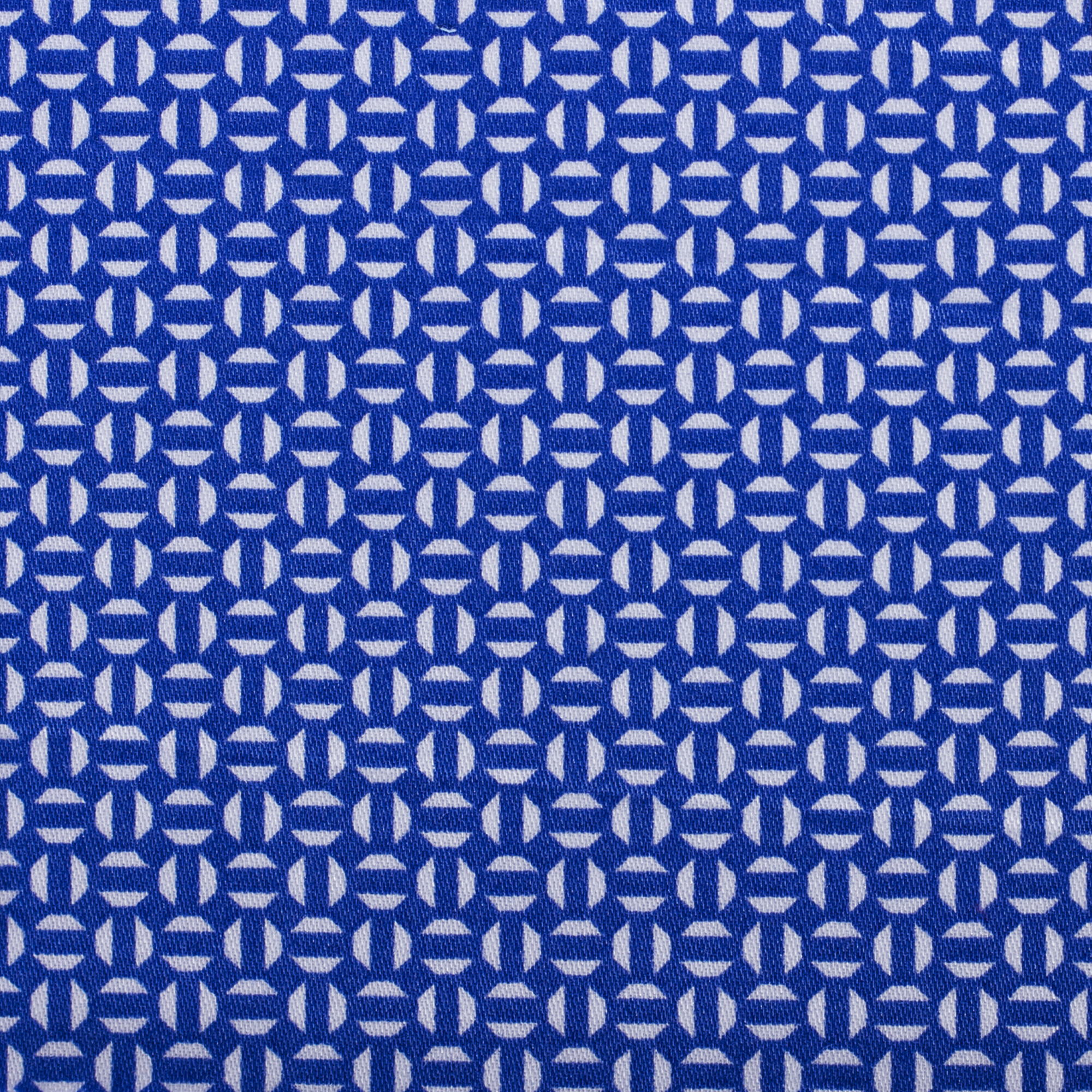

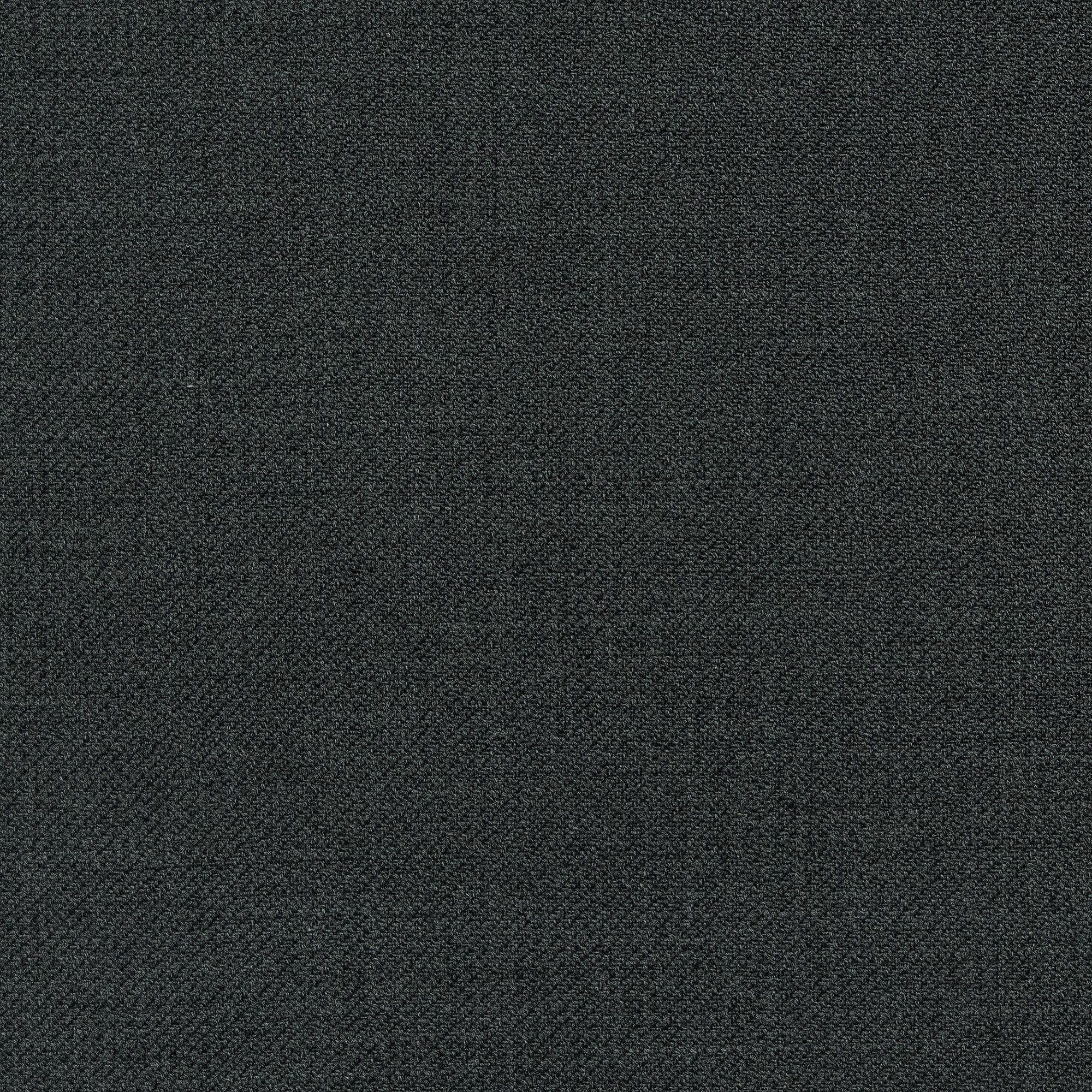

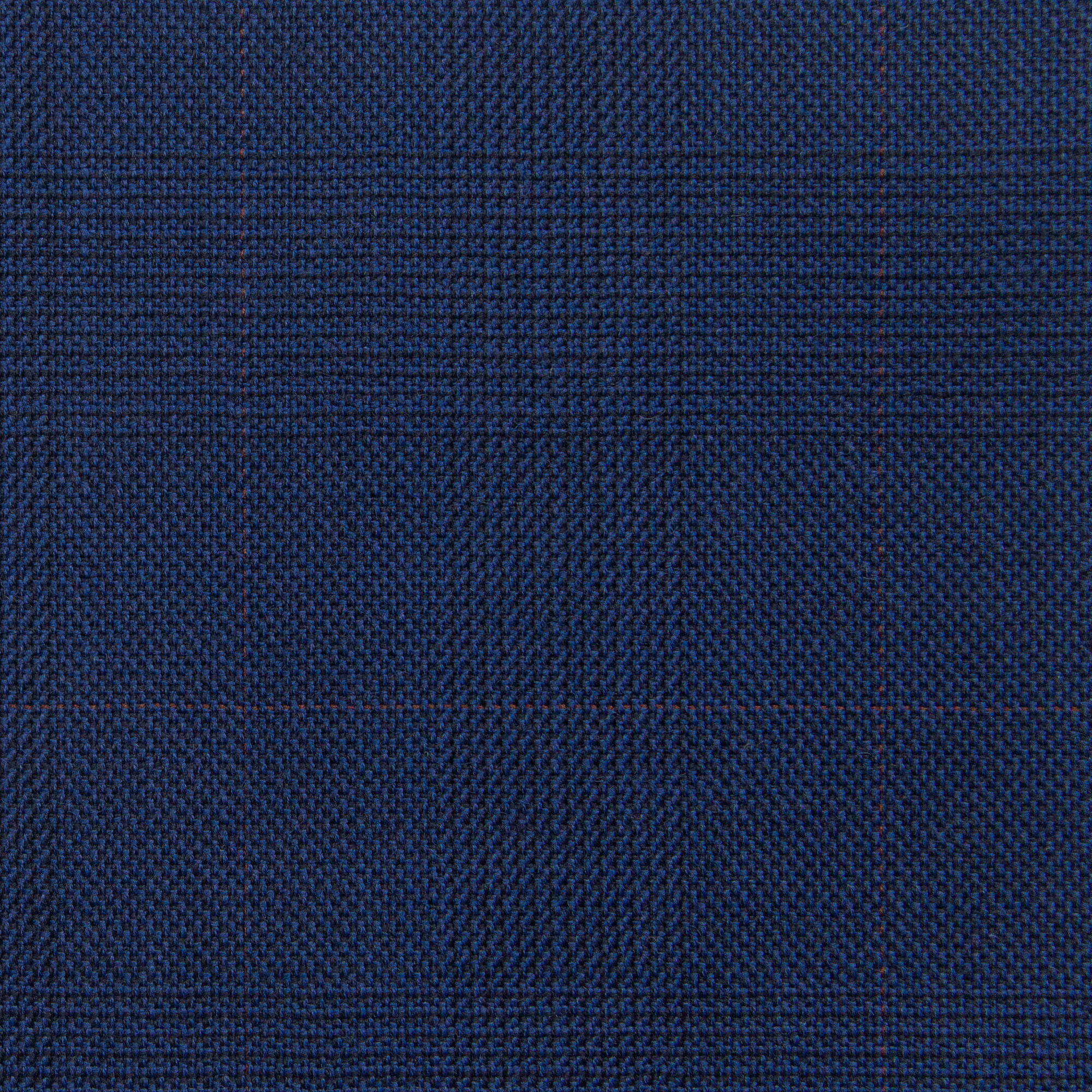

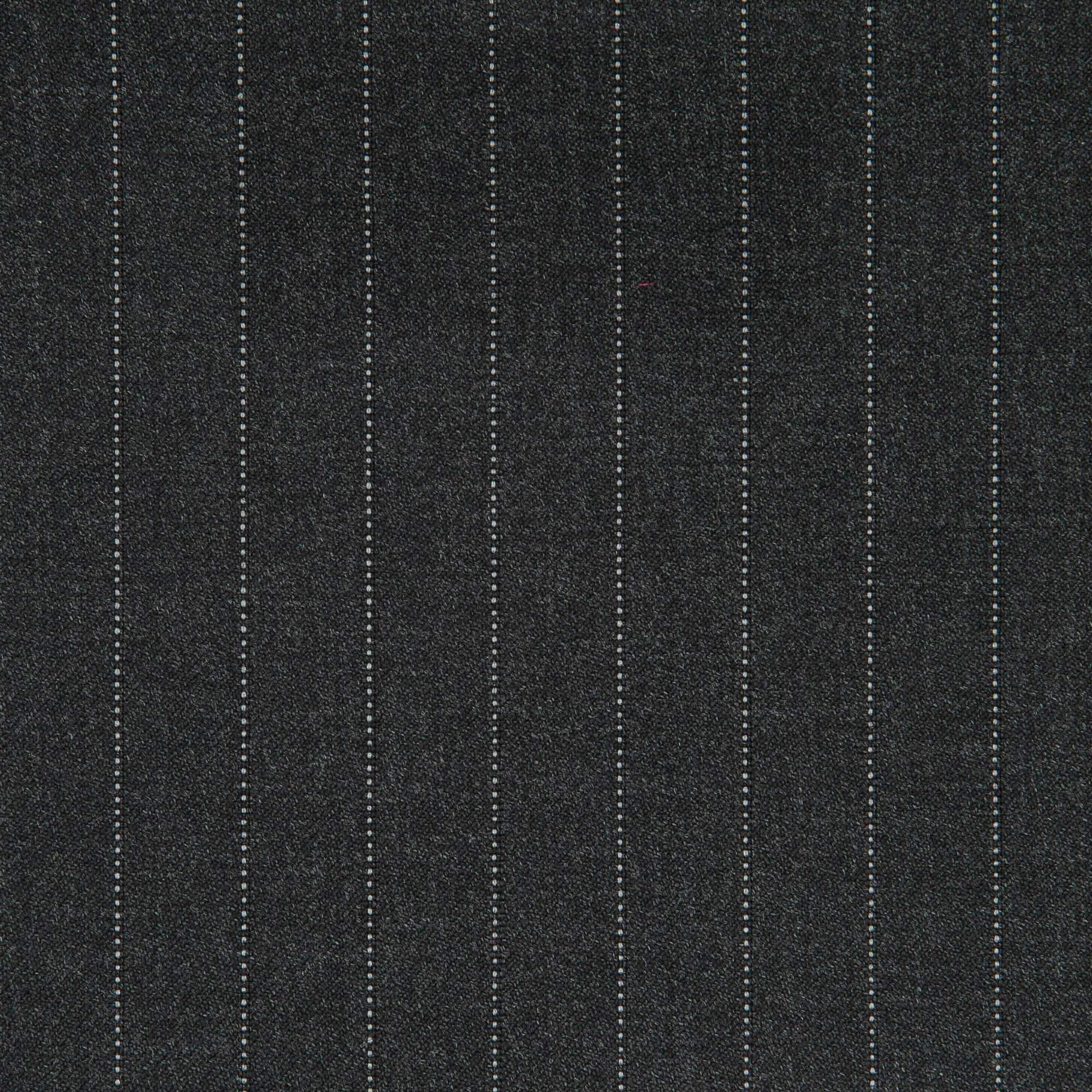

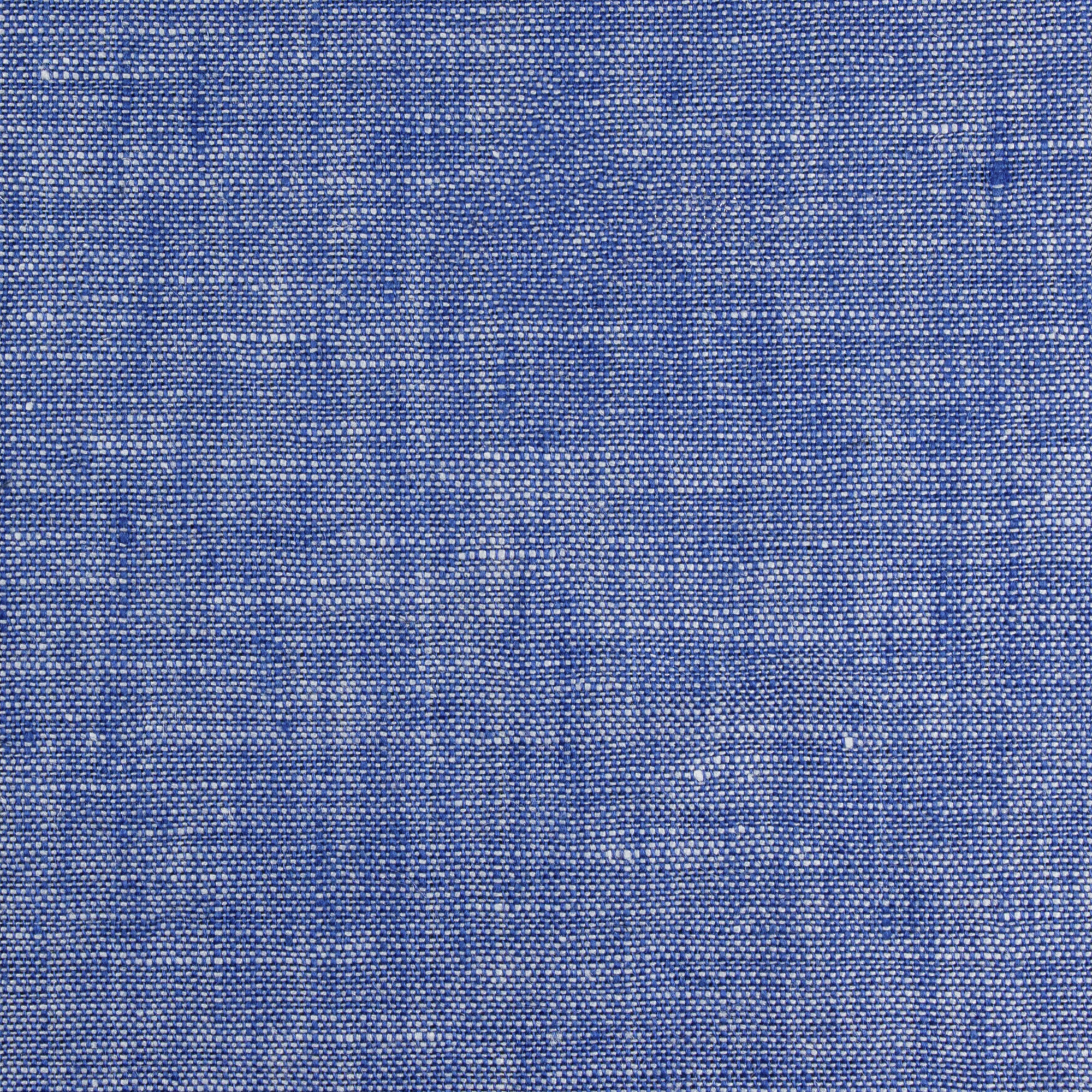

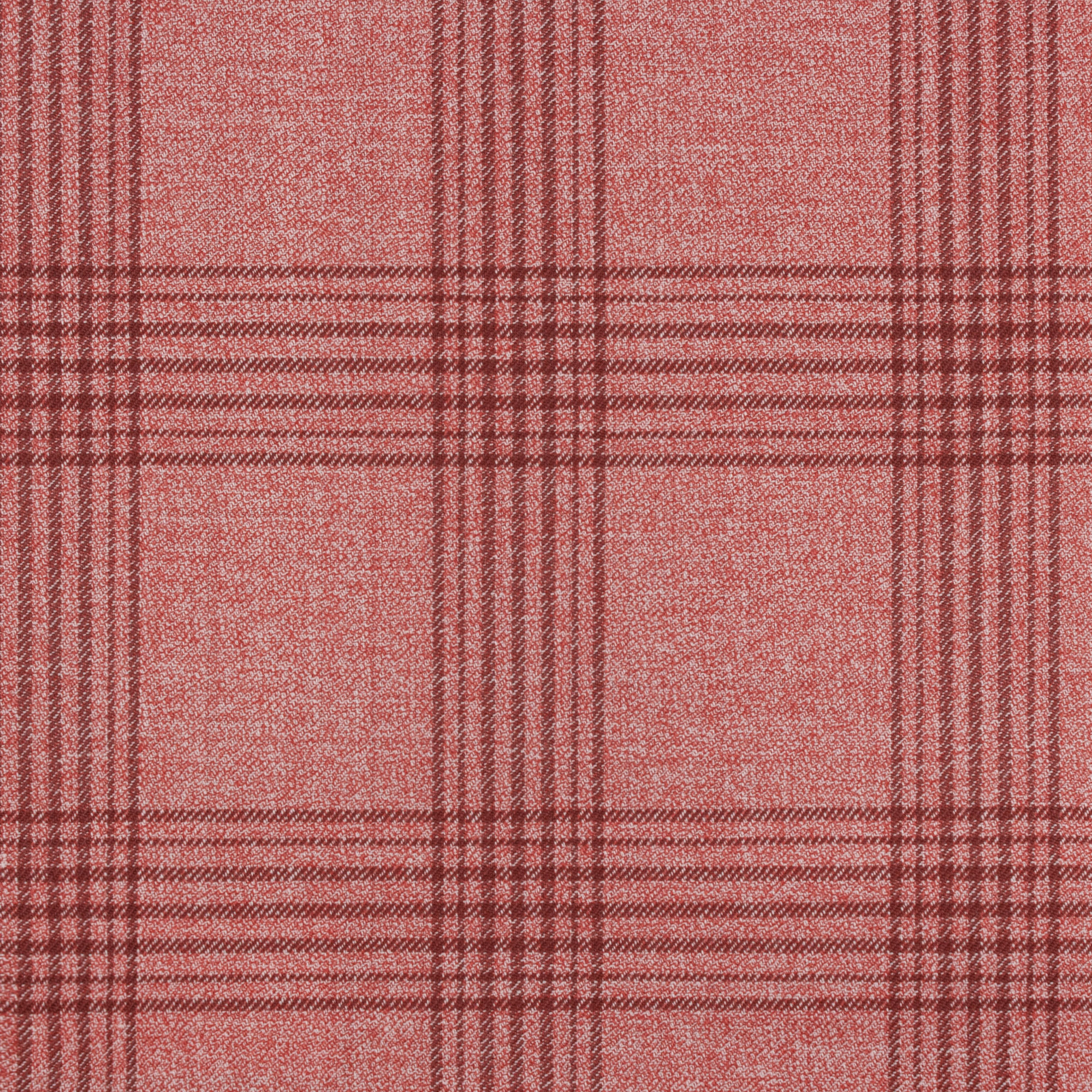

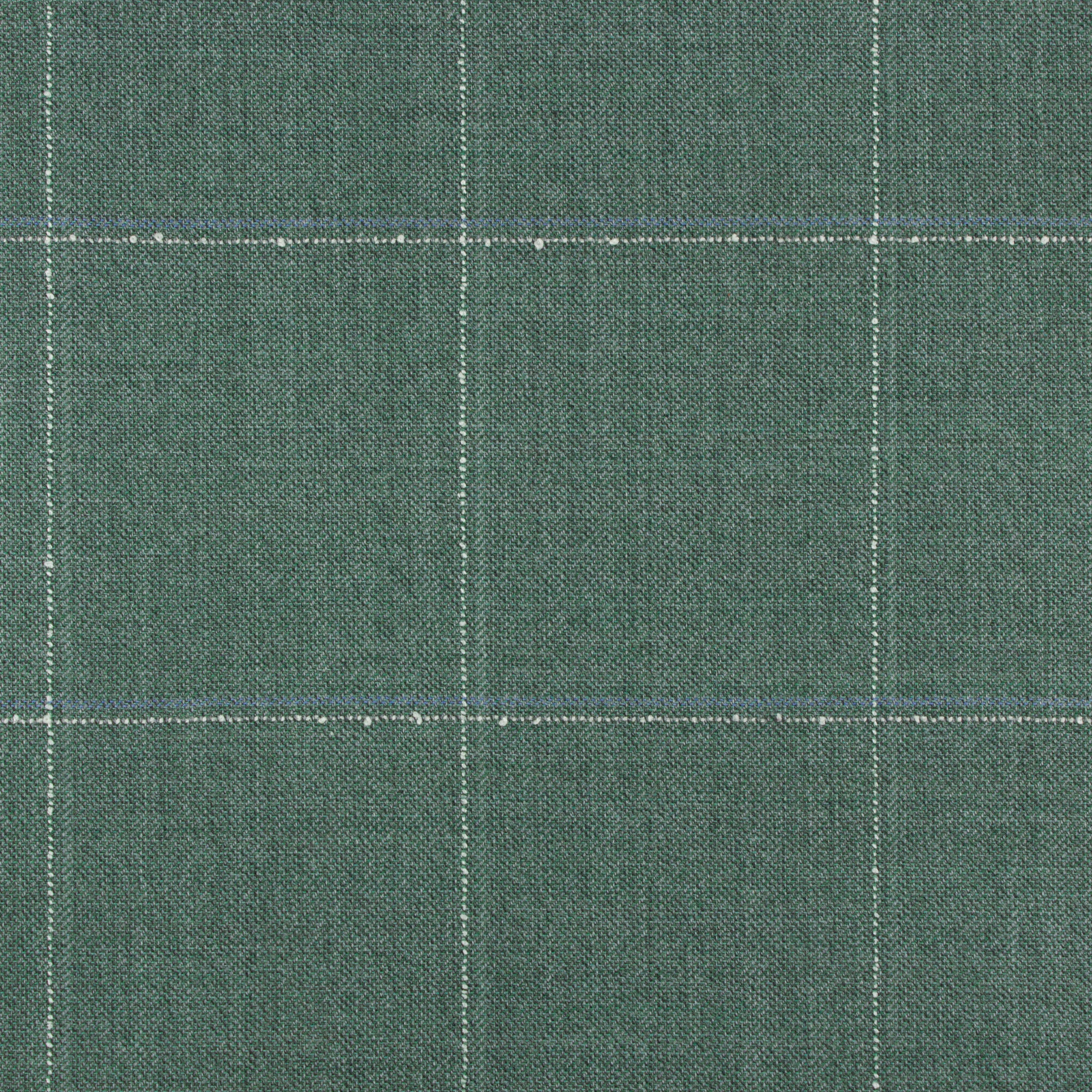

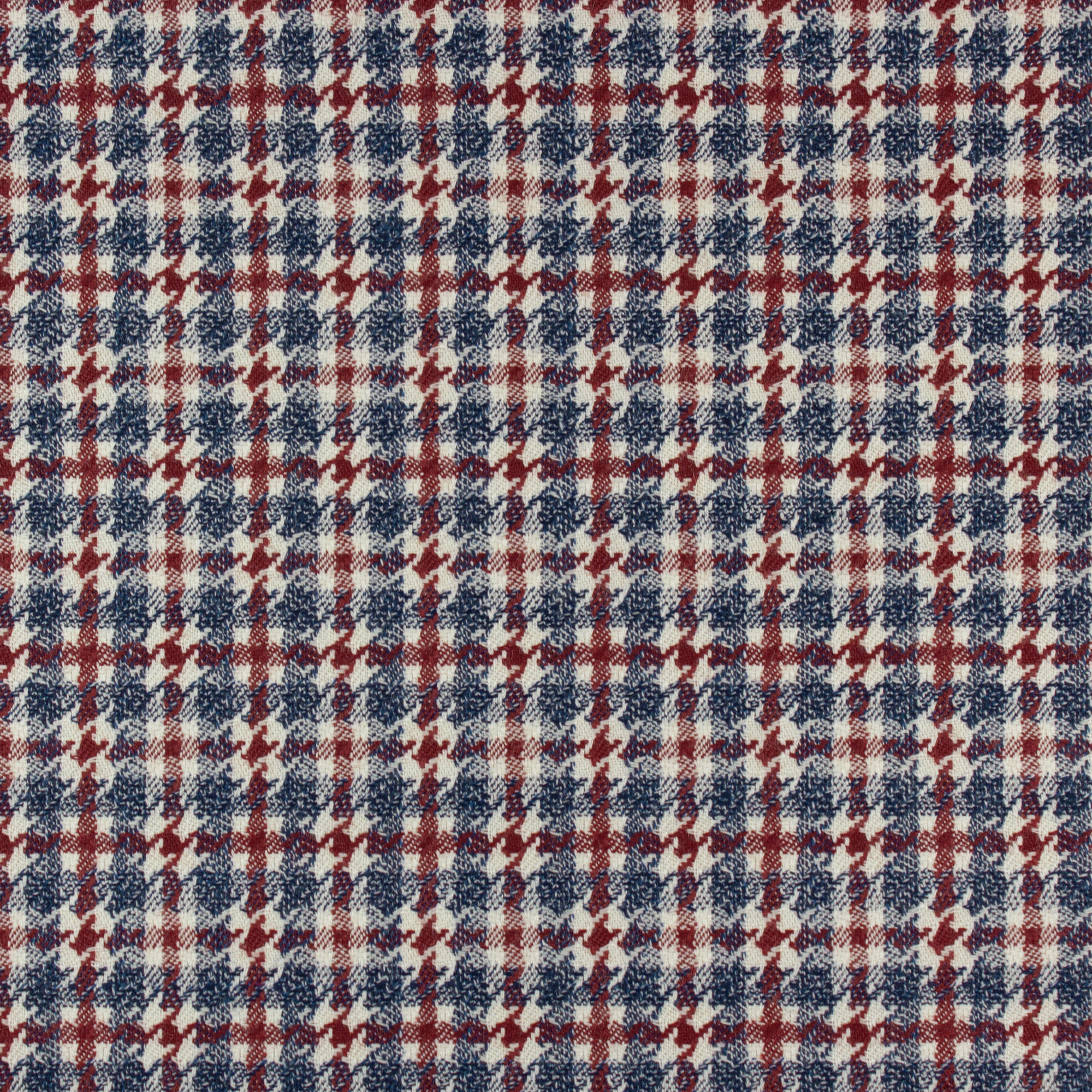

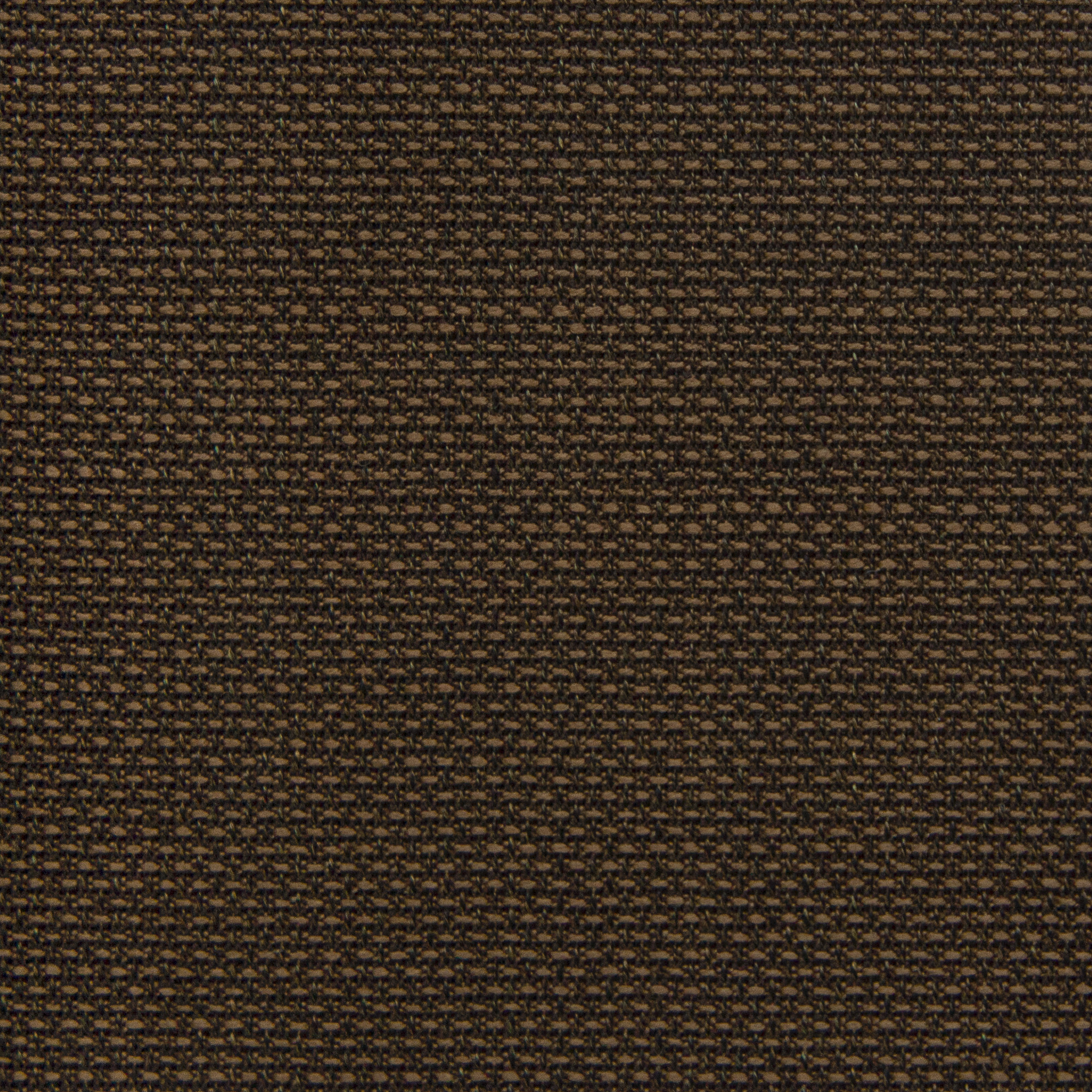

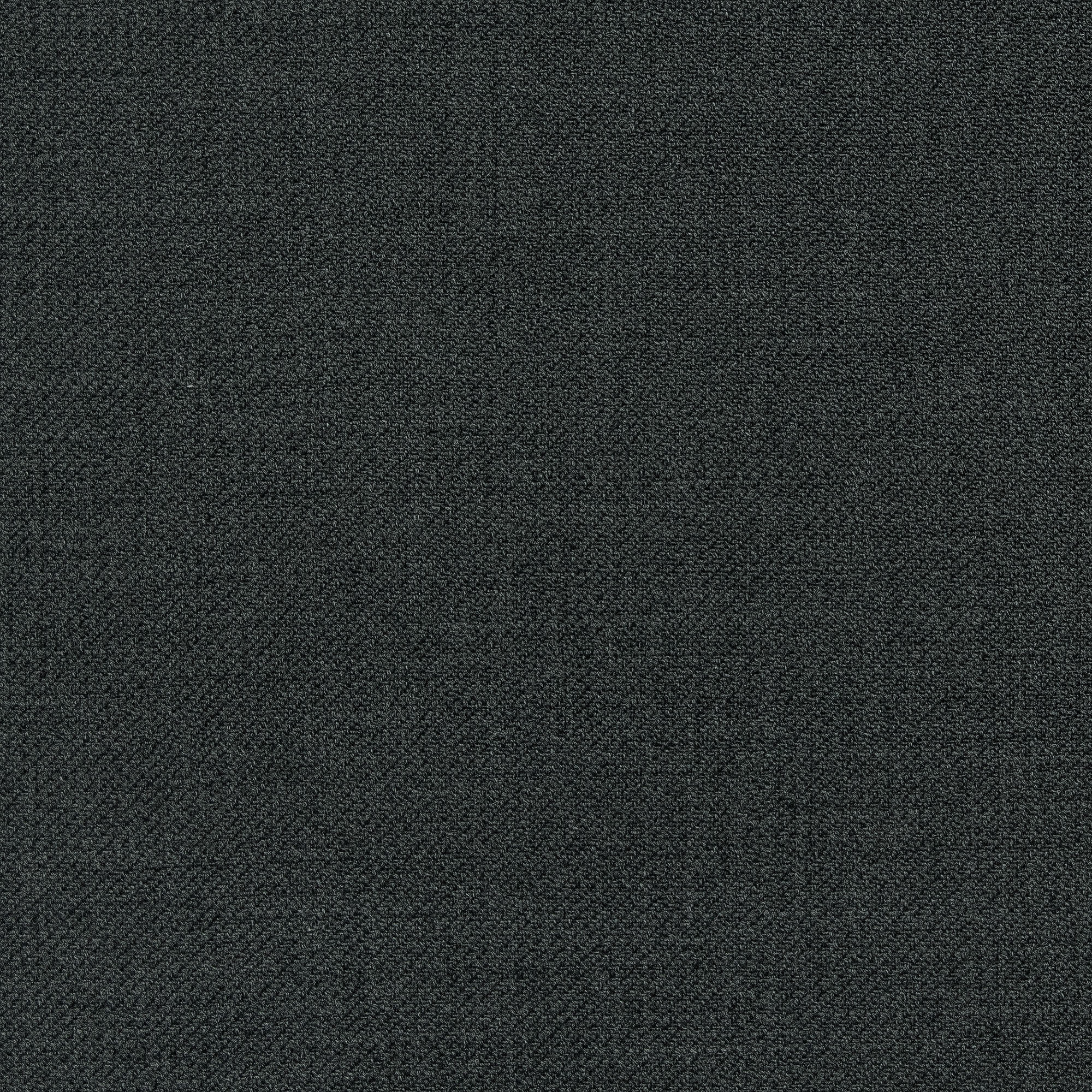

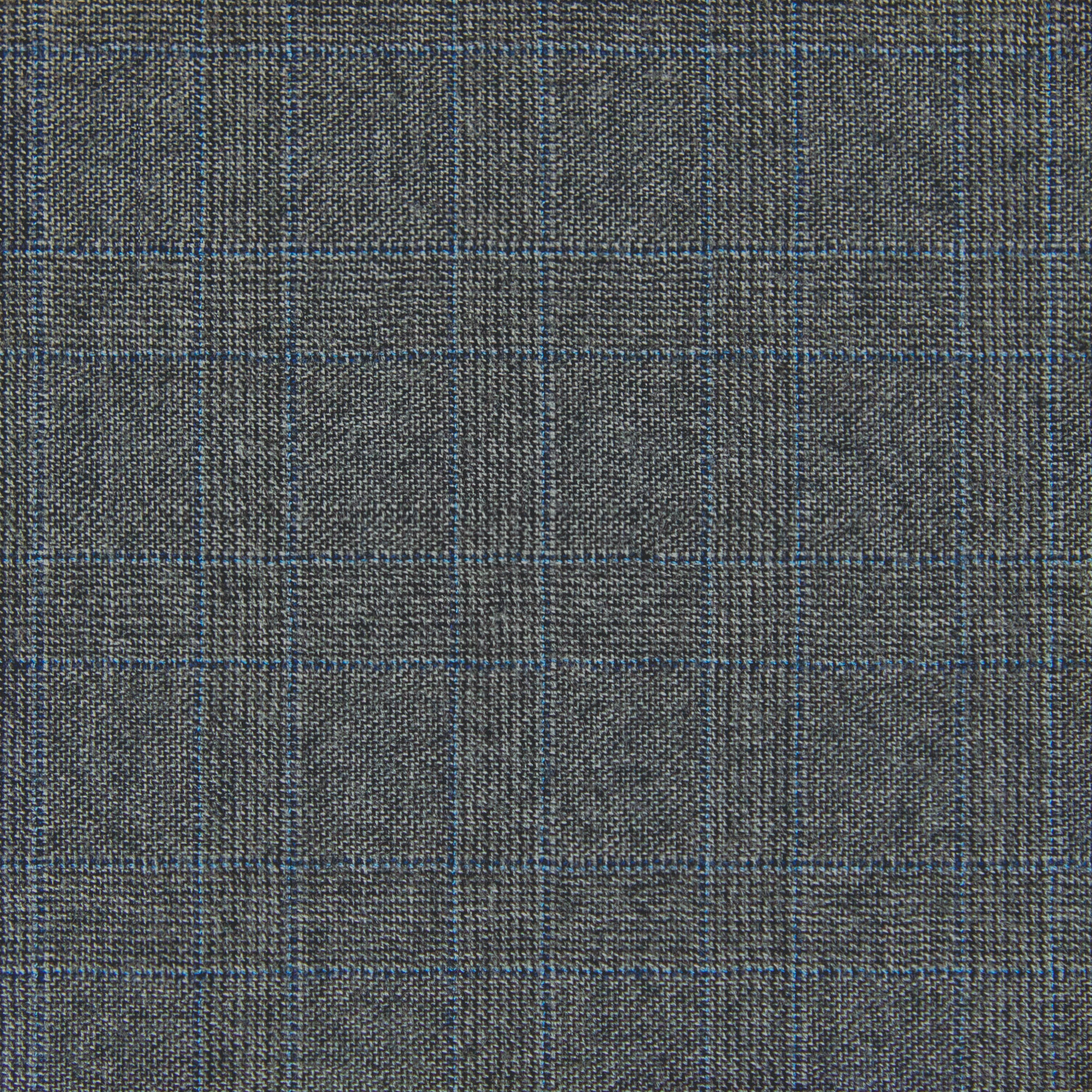

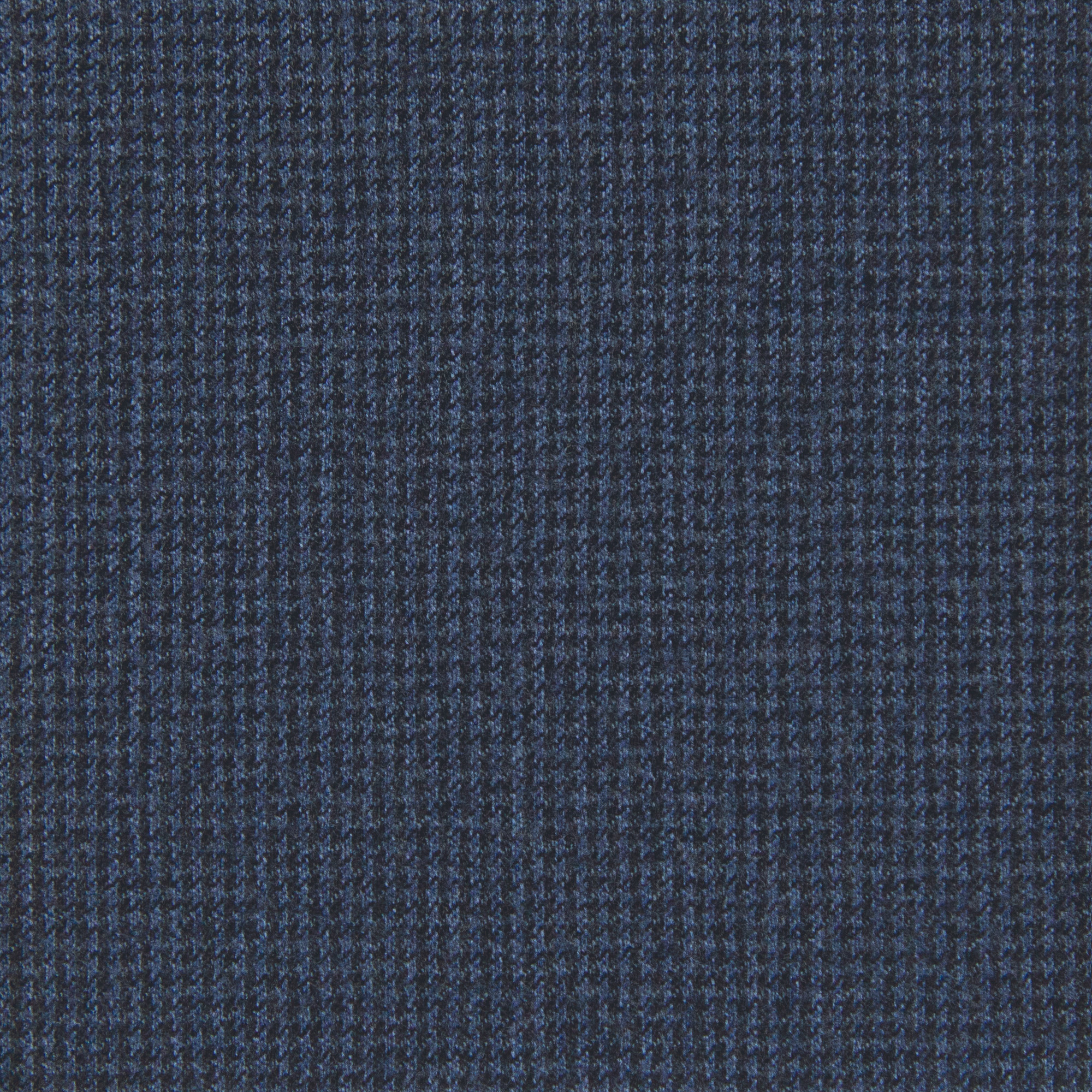

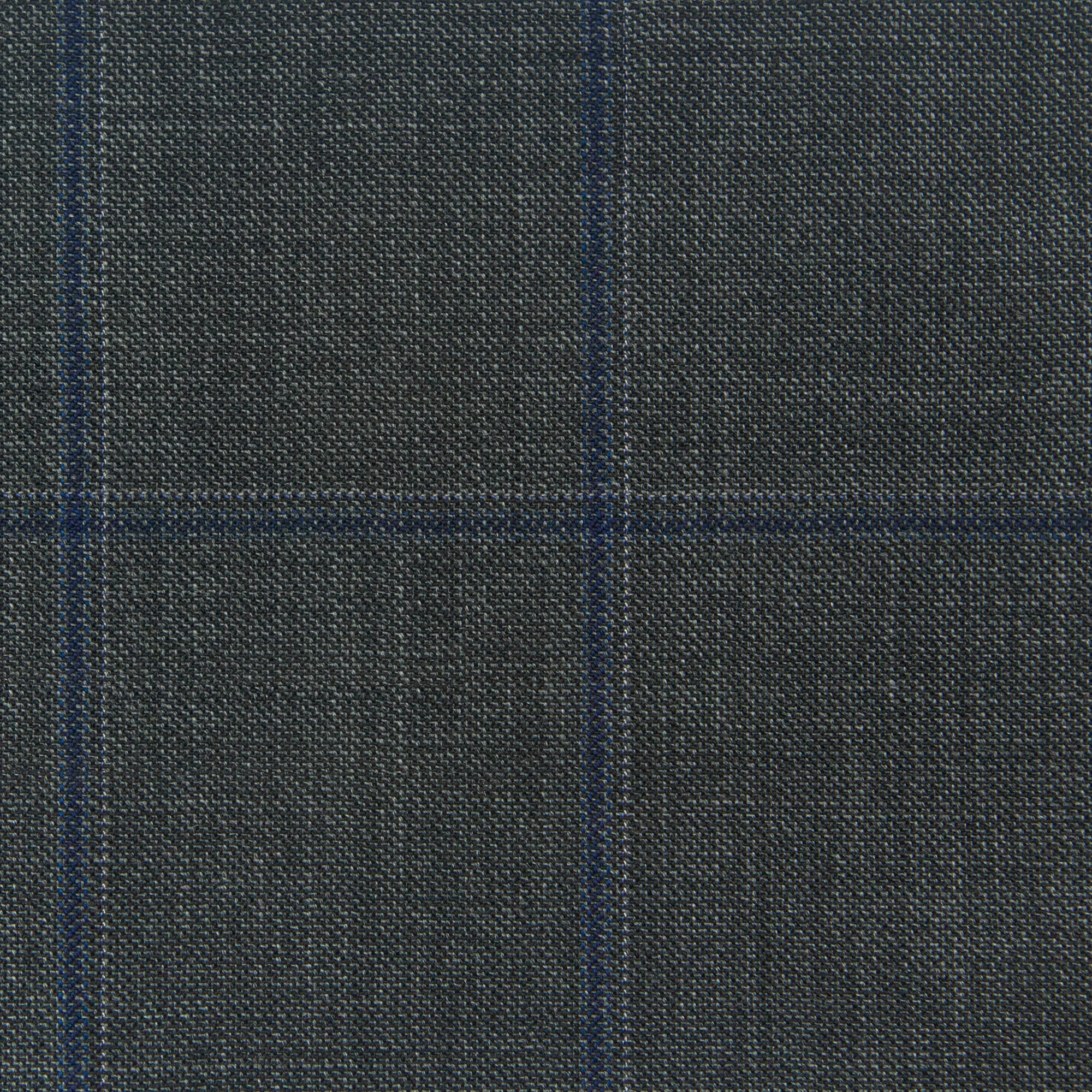

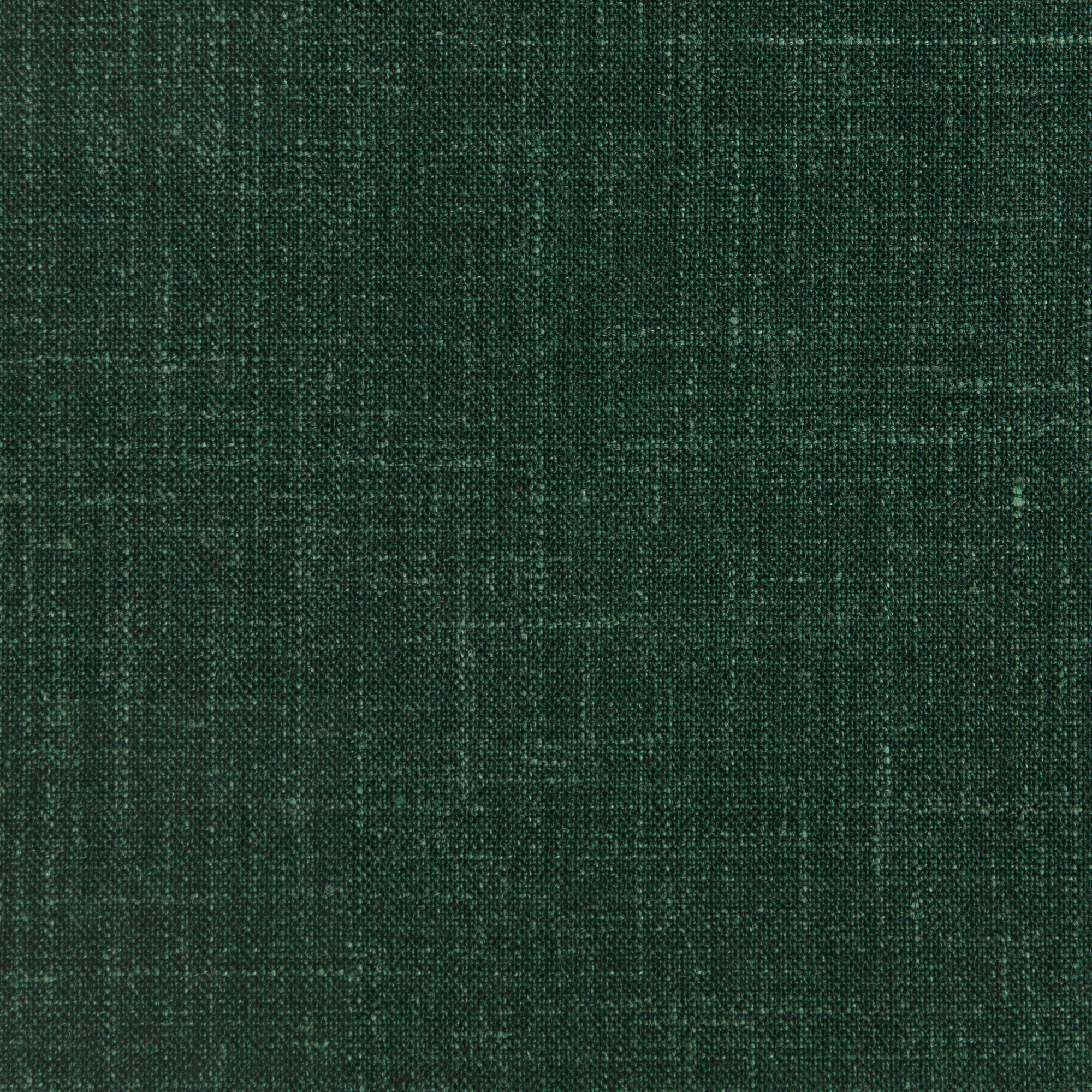

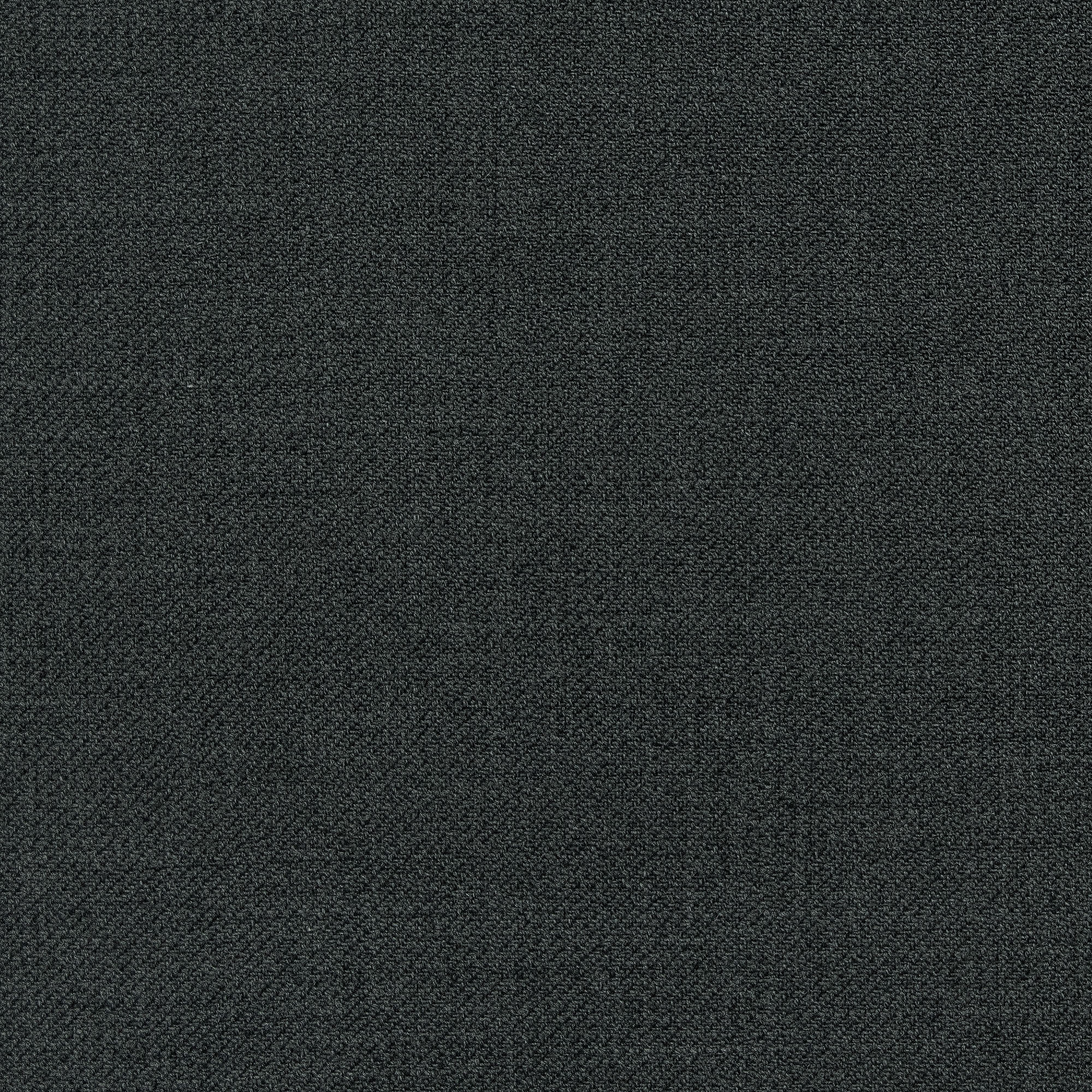

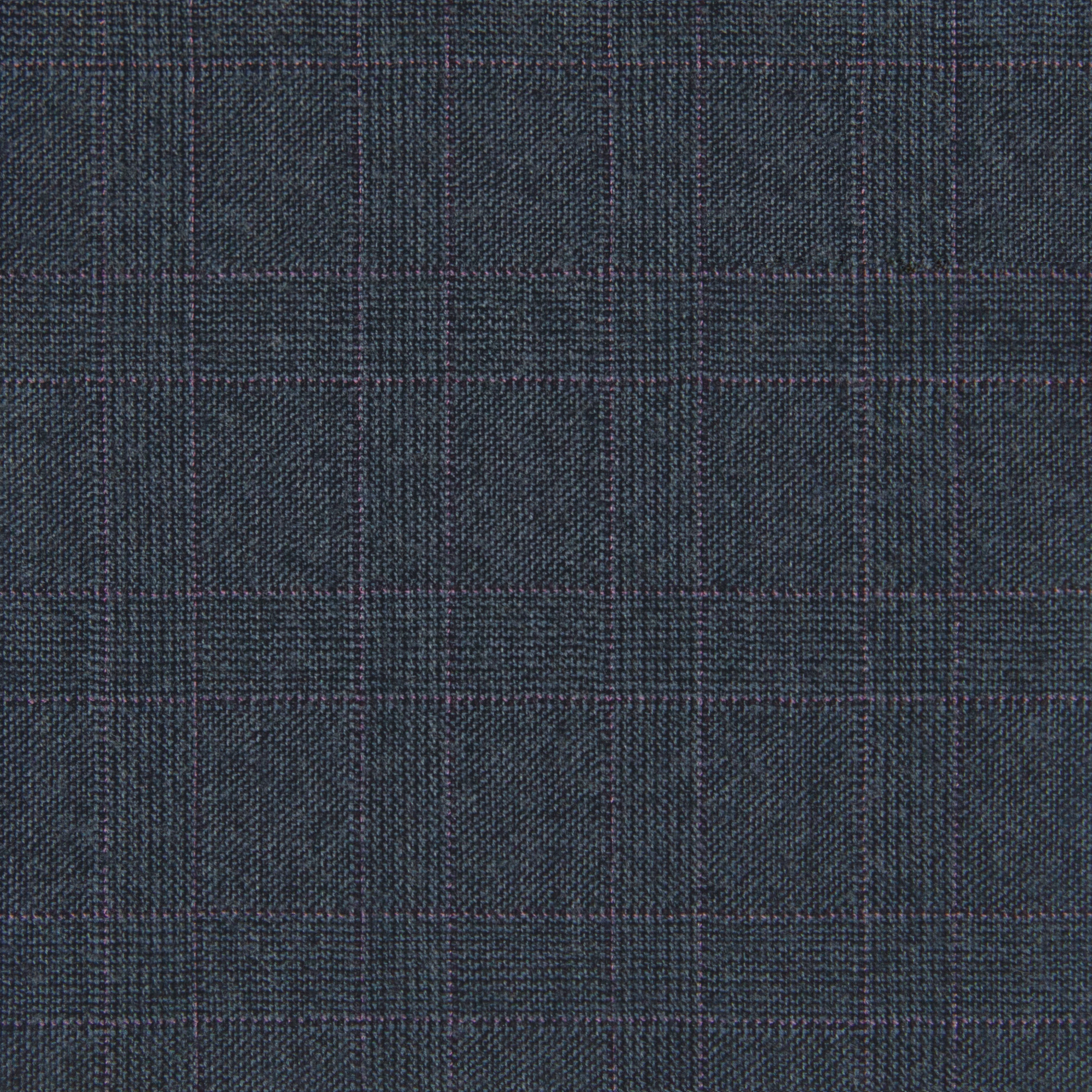

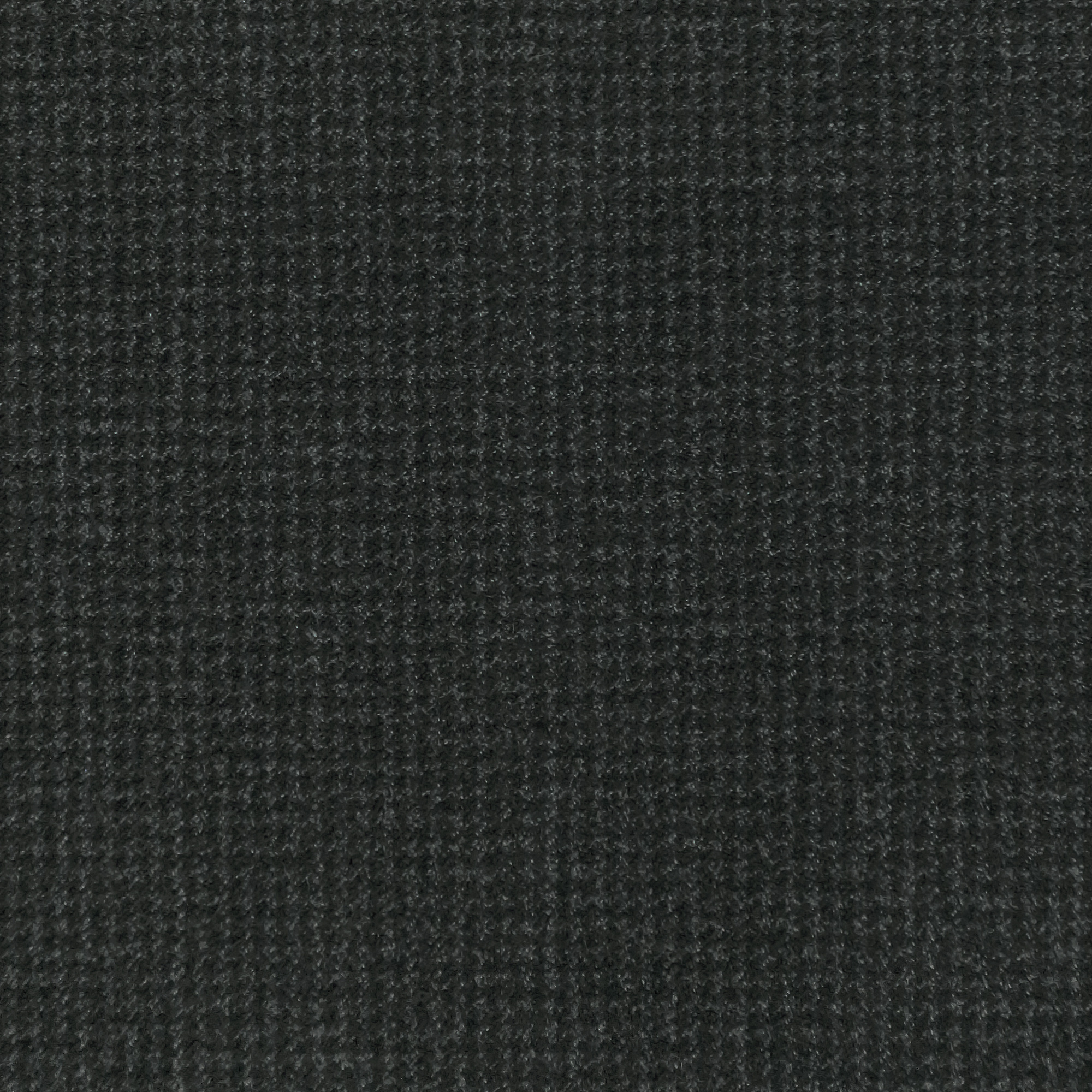

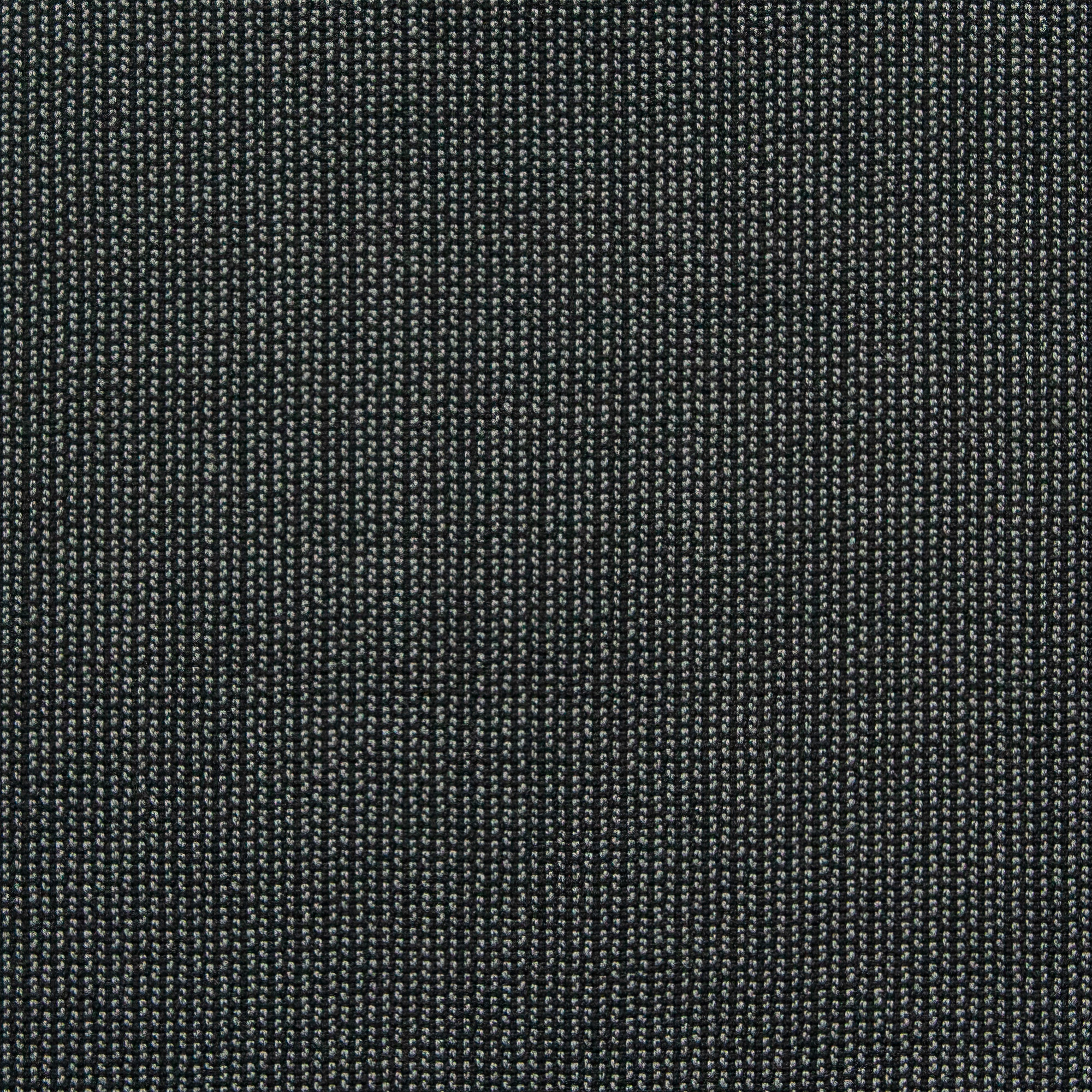

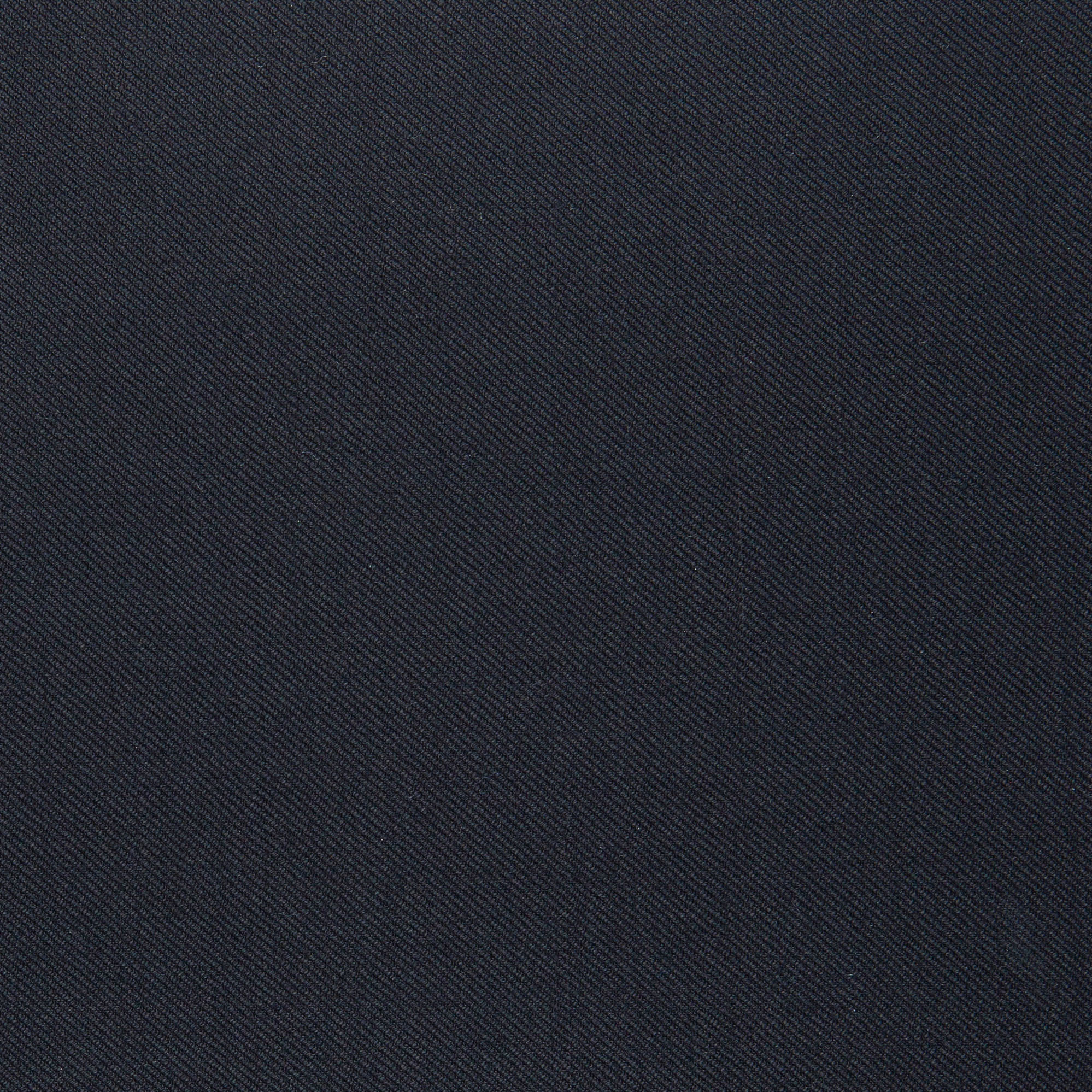

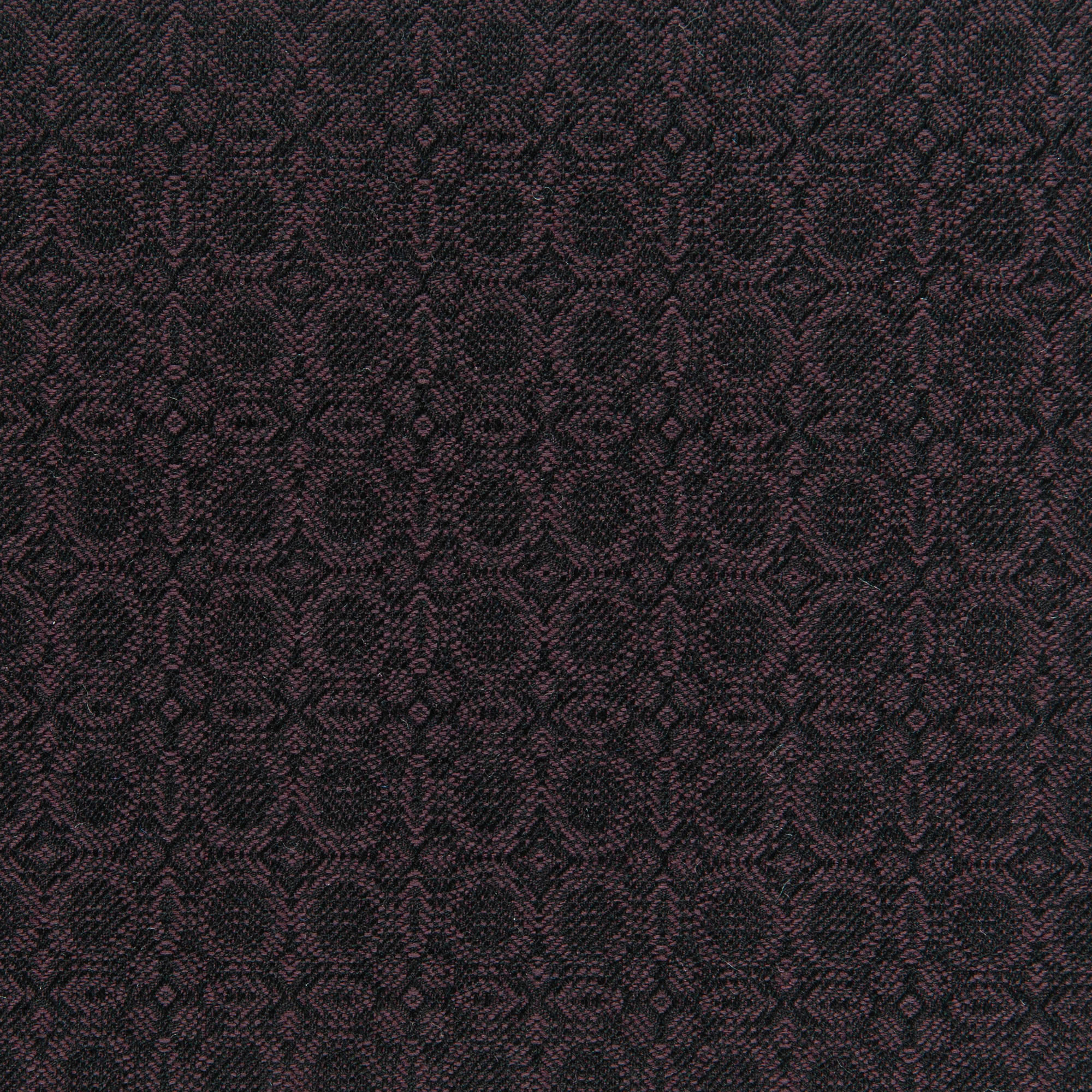

Fabric Selection

With our individually curated swatch books (or bunches), you can choose from more than 3000 fabrics. Once you’ve selected a fabric from a book, we send it off to our tailors’ workshop.

Tailoring

At Senszio, we keep alive the ancient art of bespoke tailoring, yet always keep it current with a selection of contemporary men’s styles.

Well after the wool is harvested from sheep and fabric is spun and woven into fabric and supplied to us is when we take over the next steps of the process. The tailoring process begins with the cut and strike. Our cutter uses your measurements (which we store) to construct and cut a paper pattern – which we store for many years – consisting of five templates. We place the pattern on the fabric and it’s ‘striked’ (cut).

The master tailor then receives the pattern and the fabric, plus the lining, the collar, canvas and Melton, the body-panel materials, and the buttons and button-hole twist.

The presser smoothes the fabric and the tailor fine-stitches the templates using hand-silk threads, finishing the shoulders by hand. We then securely machine-in the side seams, facings and pockets, insert the hand-padded body canvas and handmade shoulder pads, and press the suit.

Quality Control

We have a rigorous two-stage quality-control process. Every suit and shirt is checked meticulously by our team. Our founder then personally rechecks the suit for key measurements to very high tolerances. For example, a measurement that’s off by more than 1/4 of an inch will mean the suit or shirt being sent back for alteration. After six-eight weeks, we dispatch the suit.

Aftercare by you

Care for your new bespoke suit by allowing it to breathe. Keep it out of a non-breathable hanging bag and on a suit hanger, preferably cedar wood, and never wear it two days running. We provide a cotton suit carrying bag along with a hanger that is great for long-term suit storage in your wardrobe because the cotton allows airflow. Keep lavender leaves in pouches in the pockets to keep those moths at bay.

Don’t dry-clean your suit every few weeks, as the chemicals can wear away the wool. If it’s just wrinkled, have it pressed. In fact, a trouser press is a good investment for your suit pants. Use a clothes brush and hand-steamer for stains. For more details about aftercare, such as for specific fabric types and stains, check out our detailed aftercare posts on those subjects.

Aftercare by Senszio

We keep your unique blueprint in our pattern library for years. So reordering couldn’t be simpler. There’s no charge for alterations for up to three months after delivery.

Find out more about Senszio’s traveling-tailor service here.