THE BRIEFING

The modern gentleman’s guide to choosing a perfectly-fitted suit, the pleasures of custom tailoring and how to style yours today.

STYLE GUIDE

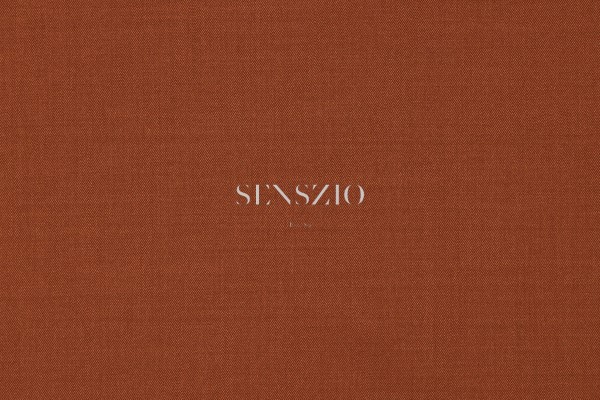

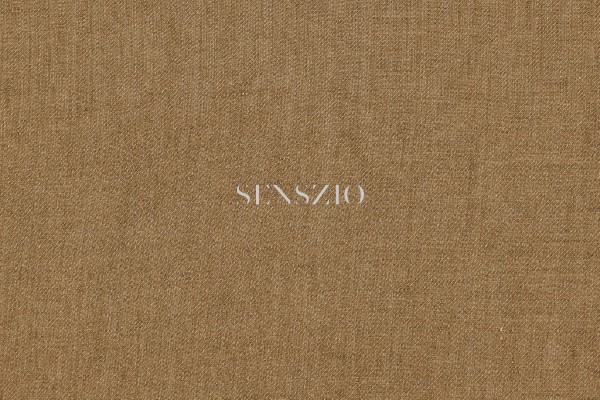

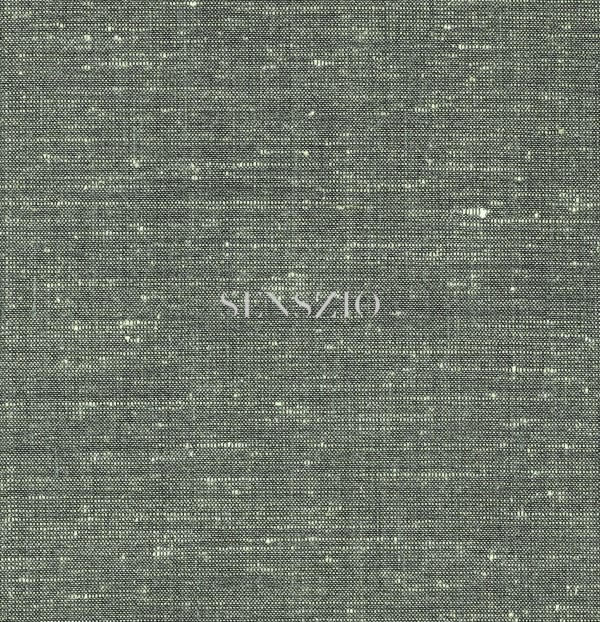

Fall/Winter Lookbook 2023/2024

Browse our range of custom tailored menswear products in our 2023 Fall/Winter Lookbook.

Where comfort and cool meet customization and quality. The Senszio custom-tailored experience covers all the pieces and looks you rely on from day to day.

Select from our new range of tailored casualwear:

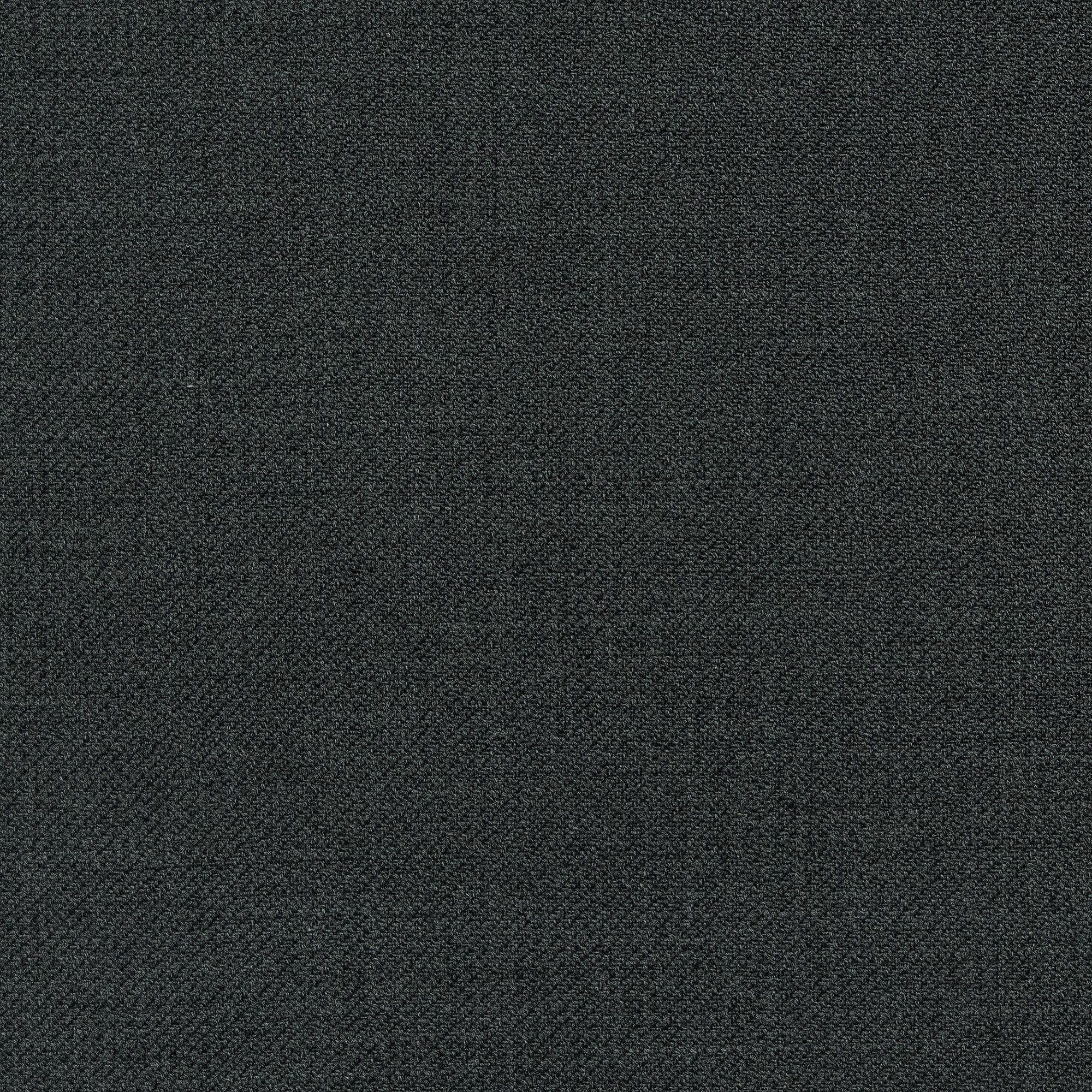

- Custom Tailored Removable Collar Winter Jacket

- Custom Tailored Insulated Field Jacket

- Custom Tailored 2-Way Single Breasted Jacket

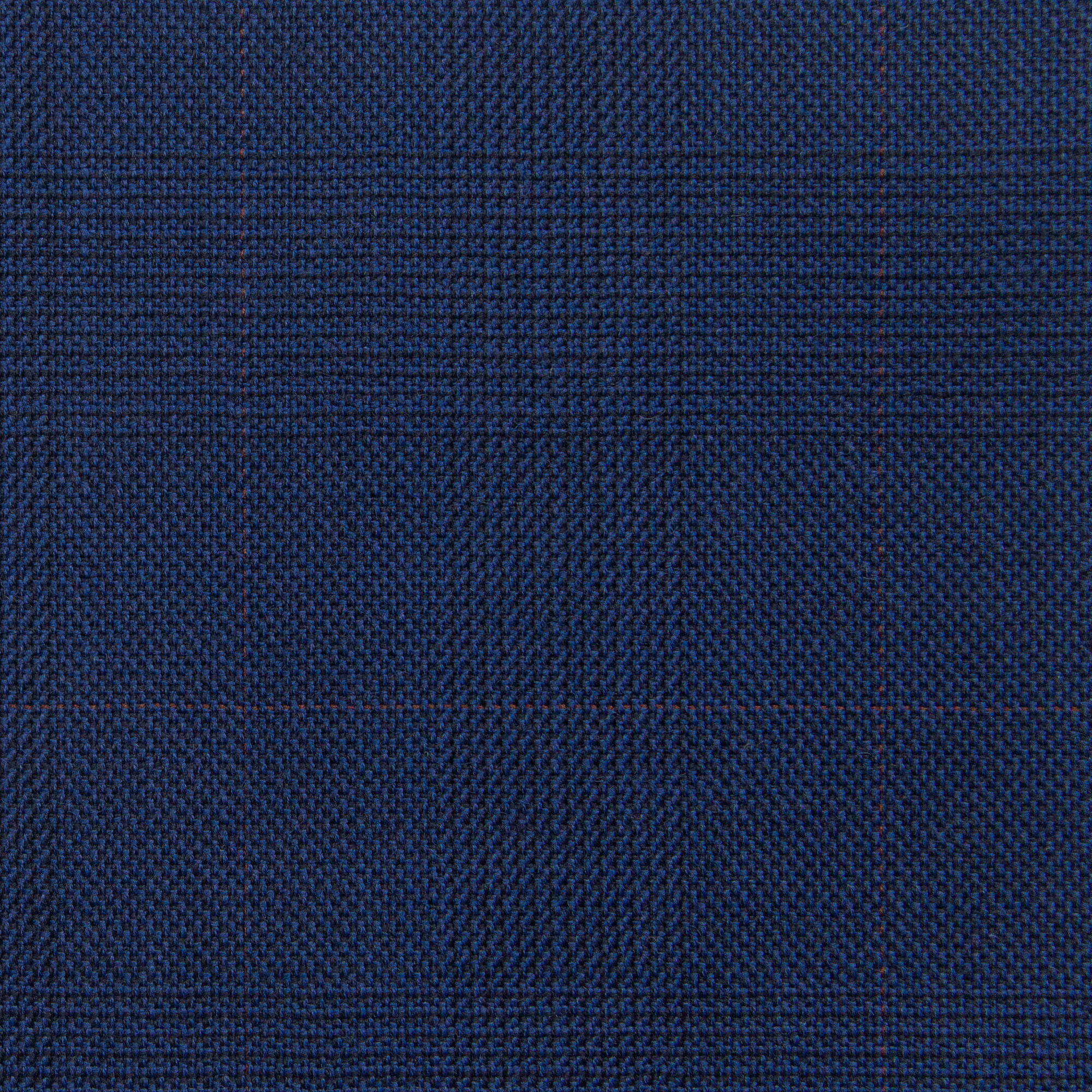

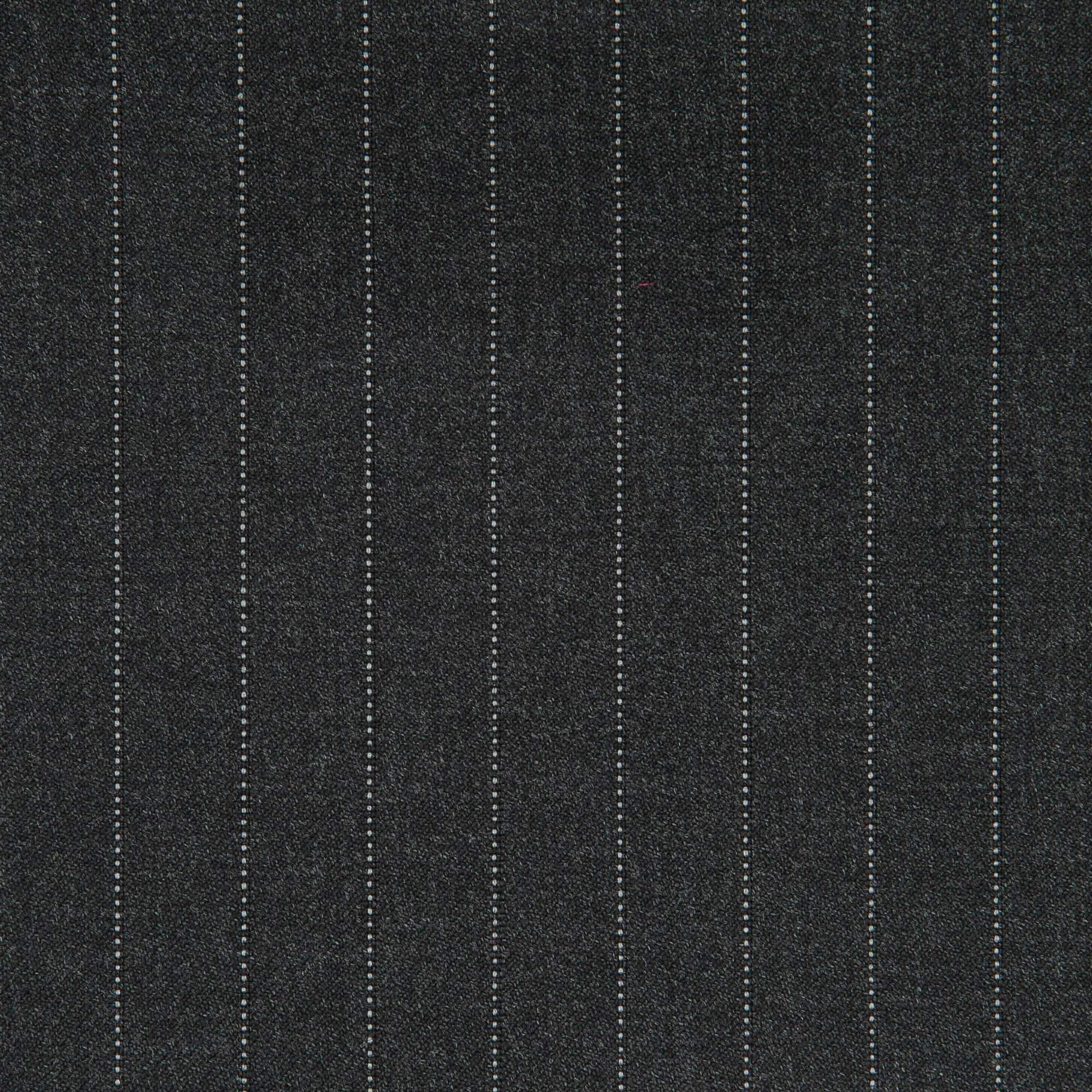

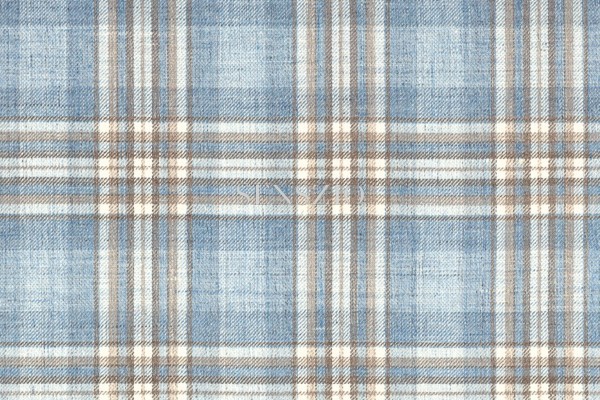

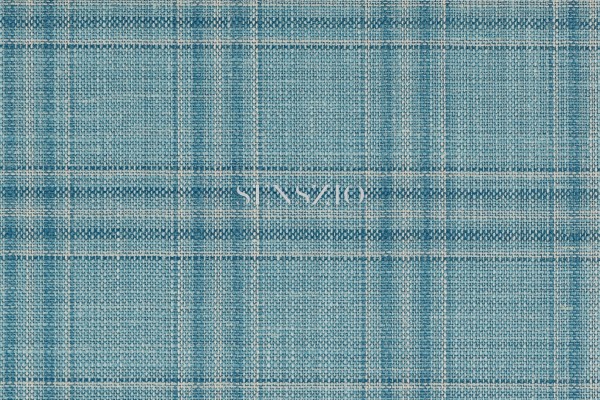

- Custom Tailored Flannel Sport Jacket

- Custom Tailored Half-Lining Unconstructed Jacket

- Custom Tailored Winter Shirt Jacket

- Custom Tailored Trenchcoat

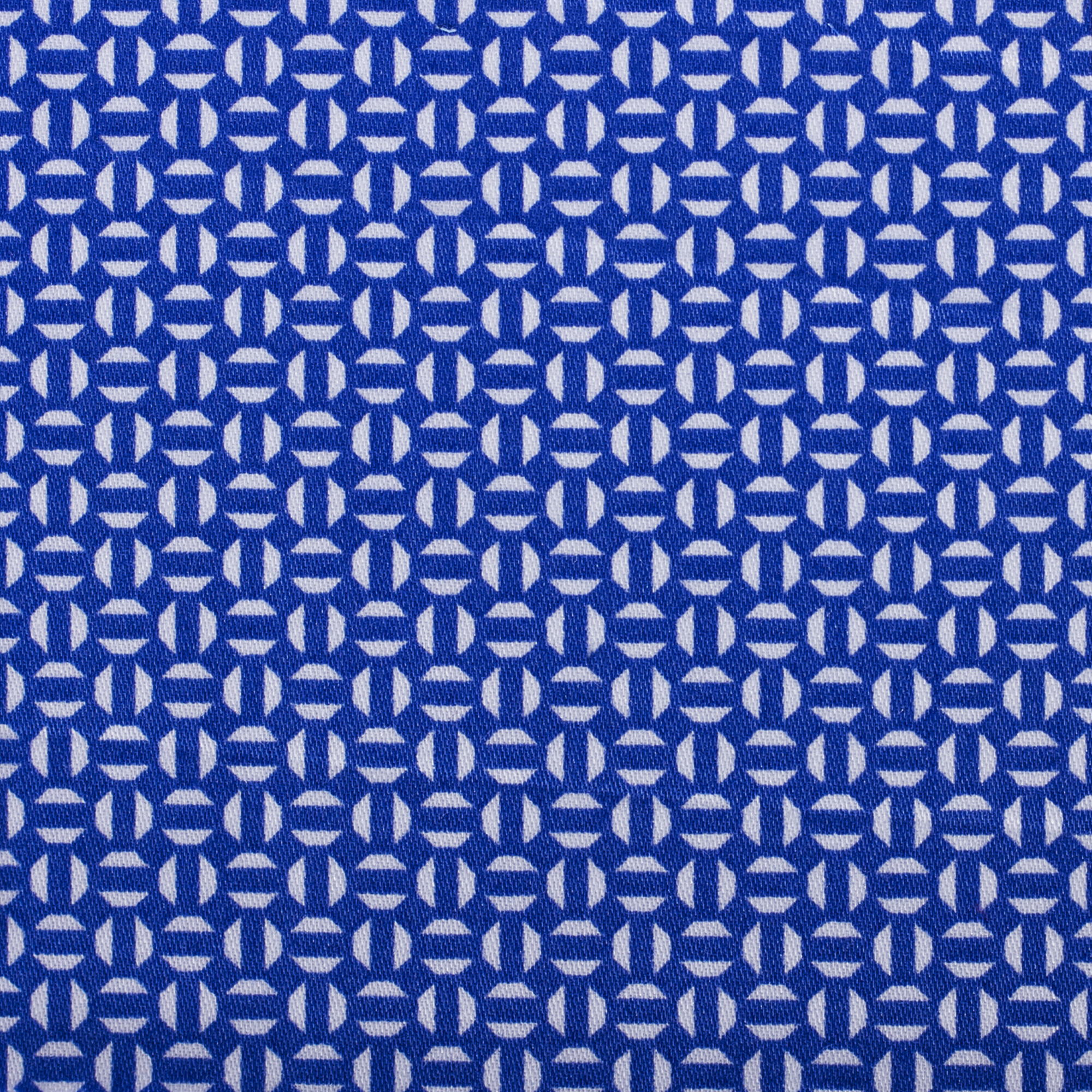

- Custom Tailored Print Shirts

- Custom Tailored Flannel Trousers

- Custom Tailored Shoes

Here’s a brief overview of the 10 new items.